Thumpstar Service Manual

IMPORTANT SAFETY NOTICE

WARNING: Indicates a strong possibility of severe personal injury or death if instructions are not followed. CAUTION: Indicates a possibility of equipment damage if instructions are not followed. NOTE: Gives helpful information.

Detailed descriptions of standard workshop procedures, safety principles, and service operations are not included. It is important to note that this manual contains some warnings and cautions against some specific service methods which could cause PERSONAL INJURY to service personnel or could damage a vehicle or render it unsafe. Please understand that those warnings could not cover all conceivable ways in which service whether or not recommended by manufacturer might be done, or of the possibly hazardous consequences of each conceivable way, nor could a manufacturer investigate all such ways. Anyone using service procedures or tools, whether or not recommended by the manufacturer, must satisfy himself thoroughly that neither personal safety nor vehicle safety will be jeopardized by the service methods or tools selected.

HOW TO USE THIS MANUAL

This service manual describes the service procedures for the Thumpstar Off Road Range.

Follow the Maintenance Schedule (Section 3) recommendations to ensure that the vehicle is in peak operation condition and the emission levels are within the standards set by the California Air Resources Board.

Performing the first scheduled maintenance is very important. It compensates for the initial wear that occurs during the break-in period.

Sections 1 and 3 apply to the whole motorcycle. Section 2 illustrates what may be required to perform service described in the following sections. Sections 4 through 14 describe parts of the motorcycle, grouped according to location.

Find the section you want on this page, then turn to the table of contents on the first page of the section.

Most sections have an assembly or system illustration, service information, and troubleshooting for the section.

The subsequent pages give detailed procedures. If you don't know the source of the trouble, go to section 16, troubleshooting.

ALL INFORMATION, ILLUSTRATIONS, DIRECTIONS, AND SPECIFICATION INCLUDED IN THIS PUBLICATION ARE BASED ON THE LATEST PRODUCT INFORMATION AVAILABLE AT THE TIME OF APPROVAL FOR PRINTING. THUMPSTAR MOTOR INC RESERVES THE RIGHT TO MAKE CHANGES AT ANY TIME WITHOUT NOTICE AND WITHOUT INCURRING ANY OBLIGATION WHATEVER. NO PART OF THIS PUBLICATION MAY BE REPRODUCED WITHOUT WRITTEN PERMISSION. THIS MANUAL IS WRITTEN FOR PERSONS WHO HAVE ACQUIRED BASIC KNOWLEDGE OF MAINTENANCE ON MANUFACTURER'S MOTORCYCLES, MOTOR SCOOTERS, OR ATVS. SERVICE PUBLICATION OFFICE

ENGINE AND DRIVE TRAIN

- LUBRICATION SYSTEM

- FUEL SYSTEM

- ENGINE REMOVAL/INSTALLATION

- CYLINDER HEAD/VALVES

- CYLINDER/PISTON

- CLUTCH/GEARSHIFT LINKAGE

- ALTERNATOR/CAM CHAIN TENSIONER

- CRANKSHAFT

T/TRANSMISSION/KICKSTARTER

CHASSIS N

- FRONT WHEEL/BRAKE/SUSPENSION/STEERING

- REAR WHEEL/BRAKE/SUSPENSION

ELECTRICAL

- IGNITION SYSTEM

- WIRING DIAGRAM

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required, it would be explained specifically in the text without the use of the symbols.

- Replace the part(s) with new one(s) before assembly

- Use recommended engine oil, unless otherwise specified.

- Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1:1)

- Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLG#2 or equivalent) Example: Molykote BR-2 plus manufactured by Dow Corning, U. S. A.

- Multi-purpose M-2 manufactured by Mitsubishi oil, Japan Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLG#2 or equivalent). Example: Molykote G-N paste manufactured by Dow Corning, U.S.A.

- Manufacture Moly 610 (U.S.A. only) Rocol ASP manufactured by Rocol Limited, U.K. Rocol Paste manufactured by Sumico Lubricant, Japan.

- Use silicone grease.

- Apply a locking agent. Use a middle strength locking agent unless otherwise specified.

- Apply sealant.

- Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified. Use Fork or Suspension Fluid.

1. GENERAL INFORMATION

GENERAL SAFETY

- CARBON MONOXIDE If the engine must be running to do some work, make sure the area is well ventilated. Never run the engine in an enclosed area.

WARNING

The exhaust contains poisonous carbon monoxide gas that can cause loss of consciousness.

Run the engine in an open area or with an exhaust evacuation system in an enclosed area.

GASOLINE

Work in a well-ventilated area. Keep cigarettes, flames or sparks away from the work area or where gasoline is stored.

WARNING

Gasoline is extremely flammable and is explosive under certain conditions. KEEP OUT OF REACH OF CHILDREN.

HOT COMPONENTS

WARNING

Engine and exhaust system parts become very hot and remain hot for some time after the engine is run. Wear insulated gloves or wait until the engine and exhaust system have cooled before handling these parts.

USED ENGINE OIL

WARNING

Used engine oil may cause skin cancer if repeatedly left in contact with the skin for prolonged periods. Although this is unlikely unless you handle used oil on a daily basis, it is still advisable to thoroughly wash your hands with soap and water as soon as possible after handling used oil. KEEP OUT OF REACH OF CHILDREN.

- Use genuine Manufacturer's recommended parts and lubricants or their equivalent. Parts that do not meet Manufacturer's design specifications may cause damage to the motorcycle.

- Use the special tools designed for this product to avoid damage and incorrect assembly.

- Use only metric tools when servicing the motorcycle. Metric bolts, nuts, and screws.

- Install new gaskets, O-ring, cotter pins, and lock plates when reassembling.

- When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque diagonally in incremental steps unless a particular sequence is specified.

- Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

- After reassembly, check all parts for proper installation and operation.

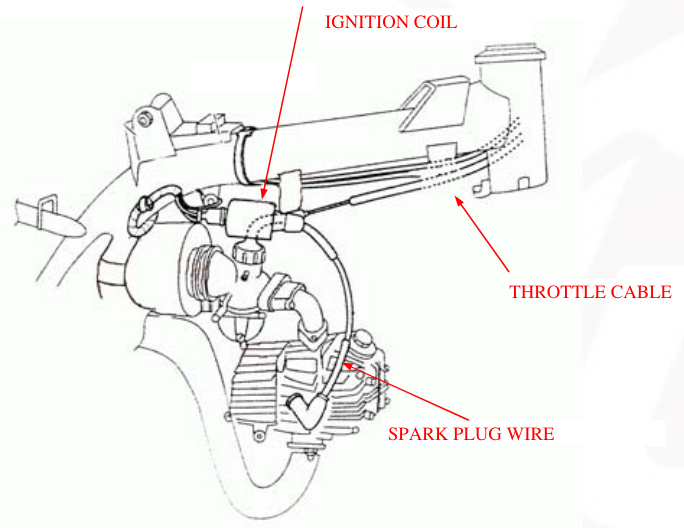

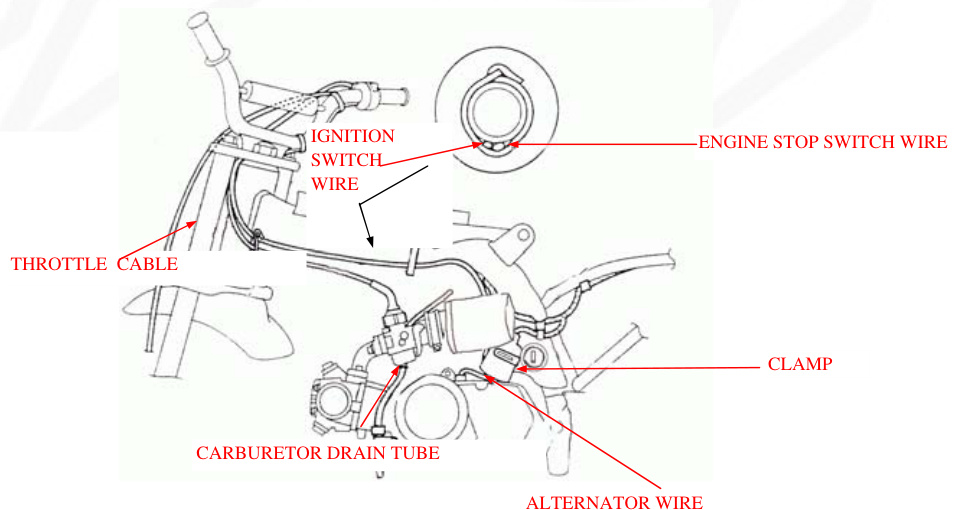

- Route all electrical wires as shown on pages 1-14 through 1-16, Cable and Harness Routing.

MODEL IDENTIFICATION

ENGINE SERIAL NUMBER

ENGINE SERIAL NUMBER

(2) The engine serial number is stamped on the lower left of the crankcase.

(2) The engine serial number is stamped on the lower left of the crankcase.

VEHICLE IDENTIFICATION (3) The vehicle identification number (VIN) is located on the right side of the steering head.

| GENERAL ITEM | SPECIFICATIONS |

|---|---|

| ENGINE | |

| Overall Length | 1,430mm(71.0 in) 760mm(30.0 in) |

| Overall width | |

| Overall height | |

| Wheelbase | 950mm(37.4 in) |

| Seat height | 990mm(38.9in) |

| 700mm(27.6 in) | |

| Foot peg height | 215mm(8.5 in) |

| Ground clearance | 240mm(9.4 in) |

| Dry weight | 60 kg (180.8 lbs) |

| FRAME |

| Type | Back bone | |

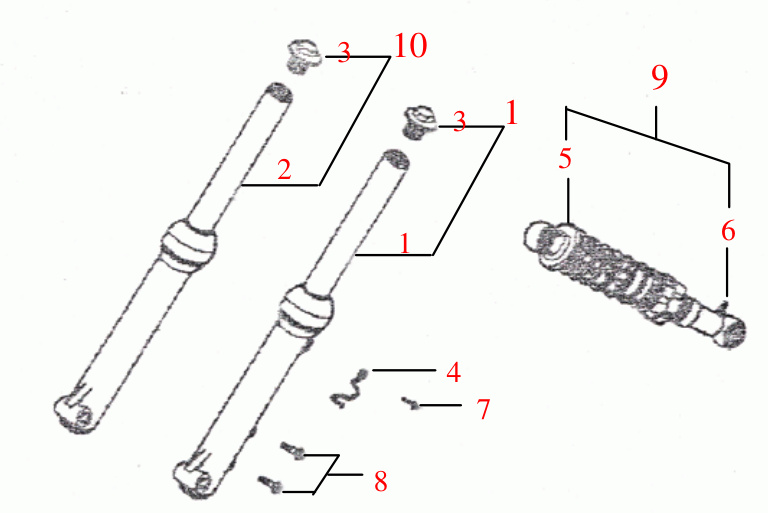

| Front suspension | Telescopic fork | |

| Rear suspension | Swingarm | |

| Rear damper | Conventional type oil damper | |

| Front tyre size | ||

| Rear Tyre | 2.50-10/12/14 | |

| Caster angle Trail length | 2.50/2.75/3.00-10/12 Front/Rear:C-183A-3 | |

| Fuel tank capacity | ||

| Fuel tank reserve capacity | ||

| Internal expanding shoe | ||

| Internal expanding shoe | ||

| Fuel tank capacity | ||

| 26° 35mm(1.4 in) | ||

| 3.0L(0.79 US gal, 0.66 Imp gal | ||

| Bore and stroke | 0.9L(0.24 US gal, 0.20 Imp gal) 90cc 47mmx49.5mm 110cc52.4mmx49.5mm | |

| Displacement | 125cc52.4mmx57mm |

| Compression ratio | Details |

|---|---|

| 90cc | 86ml |

| 110cc | 107ml |

| 125cc | 122.7ml |

| Valvetrain | Details |

|---|---|

| 90cc | 9.0.1 |

| 110cc | 9.7.1 |

| 125cc | 9.0.1 |

| Intake valve opens at 1mm | 7.5°BTDC | | Chaindriven OHC with rocker arm | | Exhaust valve opens lift | 12.5°ABDC |

| Lubrication system | 2.5°BTDC | | | Forced pressure and wet sump | | | Oil pump type | Trochoid | | | Air filtration | Foam Style | | | Crankshaft type | Oiled polyurethane foam | | | Engine dry weight | Assembled type | | | Cylinder arrangement | 21kg (46.3lbs) |

| DRIVE TRAIN | Details |

|---|---|

| Clutch system | Clutch operation system |

| Multi-plate, wet Automatic centrifugal | |

| Transmission | Primary reduction Final reduction |

| 4-speed | |

| 4.059(69/17) | |

| 2.866(37/14) 1.706(36/11) | |

| Final reduction | ELECTRICAL Ignition system Starting system LUBRICATIONSYSTEM |

| CDI (Capacitive Discharge Ignition) | |

| Kickstarter and electric | |

| Engine oil capacity | |

| ITEM STANDARD 0.6(0.6US qt,0.5lmp qt) | |

| At draining | |

| Recommended engine oil |

CYLINDER HEAD VALVES

| ITEM | STANDARD |

|---|---|

| Cylinder compression Cylinder head | 981-1,177 kpa (10.0-12.0 kgf/cm2, |

| warpage | 142-171 jpsi) at 1,000 rpm |

| Valveclearance IN | 0.05±0.02 (0.002±0.001) |

| Valve, Valve guide | |

| Valvestem O.D. | EX |

| IN | 4.970-4.985 (.1957-.1963) |

| Valveguide I.D | EX |

| IN/EX | 5.000-5.012 (.1969-.1973) |

| ----------------------------- | ------------------ |

| Stem to guide clearance | IN |

| Valve seat width | EX |

| IN/EX | |

| Valve spring free length | IN/EX |

Rocker Arm Specifications

| ITEM | STANDARD |

|---|---|

| Rocker arm I.D | IN/EX |

| Rocker arm shaft O.D | 9.978-9.987 (0.3928-0.3932) |

Camshaft Specifications

| ITEM | STANDARD | SERVICE ITEM (1.8524) |

|---|---|---|

| Cam lobe height | IN | 20.003-20.123 (0.7875-0.7922) 9.91 (0.390) |

| EX | 19.994-20.114 (0.7872-0.7919) 19.66 (0.774) | |

| 19.65 (0.774) |

LUBRICATION SYSTEM

Unit: mm (in)

| ITEM | STANDARD | SERVICE ITEM (1.8524) |

|---|---|---|

| Cylinder I.D. | THUMPSTAR | |

| Out of round | THUMPSTAR | 52.45 (2.650) 0.10 (0.004) |

| Taper | 0.10 (0.004) | |

| Warpage | 0.05 (0.002) | |

| Piston mark direction | ||

| Piston | 'IN' mark facing toward the intake side 38.975-38.995 (1.5344-1.5352) 38.90 (1.531) | |

| Piston O.D. Piston O.D. measurement point | 8mm (0.3in) from bottom of skirt | |

| Piston pin bore I.D. | 13.002-13.008 (0.5119-0.5121) | 13.06 (0.514) |

| Piston pin O.D. | 12.994-13.000 (0.5116-0.5118) | 12.98 (0.511) |

| Piston-to-piston pin clearance | 0.002-0.014 (0.0001-0.0006) | 0.08 (0.003) |

| Rings | 0.015-0.050 (0.0006-0.0020) | 0.12 (0.005) |

| Piston ring-to-ring Groove clearance | Top Second | |

| Piston ring end gap | Top 0.05-0.015 (0.002-0.006) | 0.5 (0.02) |

| Second | 0.05-0.20 (0.002-0.008) | |

| --- | --- | |

| Oil (side rail) | 0.5 (0.02) | |

| 0.3-0.9 (0.01-0.04) | 1.1 (0.04) | |

| Cylinder-to-piston clearance | 0.010-0.040 (0.0004-0.0016) | 0.15 (0.006) |

| Connecting rod small end I.D. Connecting rod-to-piston pin clearance | 132.016-13.034 (0.5124-0.5131) 0.016-0.040 (0.0006-0.0016) | 13.08 (0.515) |

| 0.12 (0.005) |

| ITEM | STANDARD | SERVICE LIMIT |

|---|---|---|

| Clutch disc thickness | 2.52-2.68 (0.099-0.106) | 2.3 (0.09) |

| B | 3.32-3.48 (0.131-0.137) | 3.0 (0.12) |

| Clutch plate warpage | 0.20 (0.008) | |

| Centrifugal clutch spring free length | 22.4 (0.88) | 19.4 (0.76) |

| Primary drive gear I.D. | 21.000-21.021 |

| ITEM | STANDARD | SERVICE LIMIT |

|---|---|---|

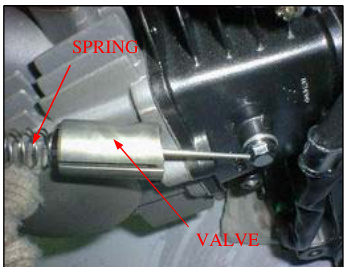

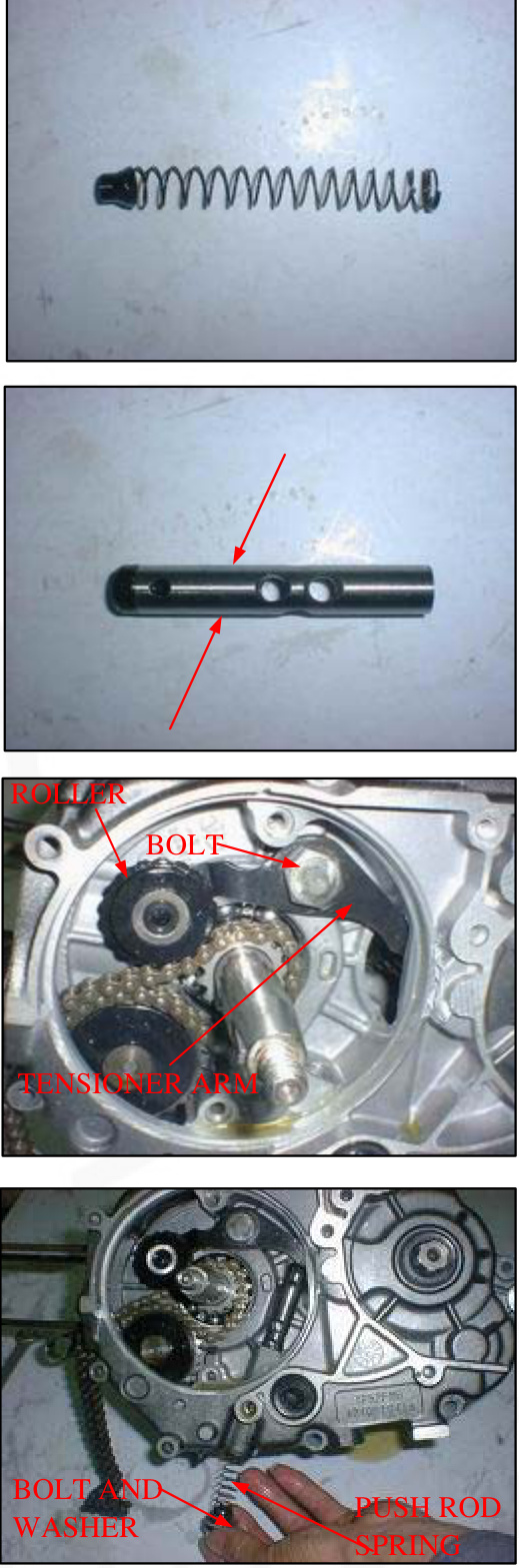

| Cam chain tensioner | ||

| Push rod O.D. | 11.985-12.000 (0.4718-0.4724) | 11.94 (0.470) |

| Spring free length | 111.3 (4.38) | 100 (3.9) |

Unit: mm (in)

ALTERNATOR/CAM CHAIN TENSIONER

| ITEM | STANDARD | SERVICE LIMIT |

|---|---|---|

| Cam chain tensioner | ||

| Push rod O.D. | 11.985-12.000 (0.4718-0.4724) | 11.94 (0.470) |

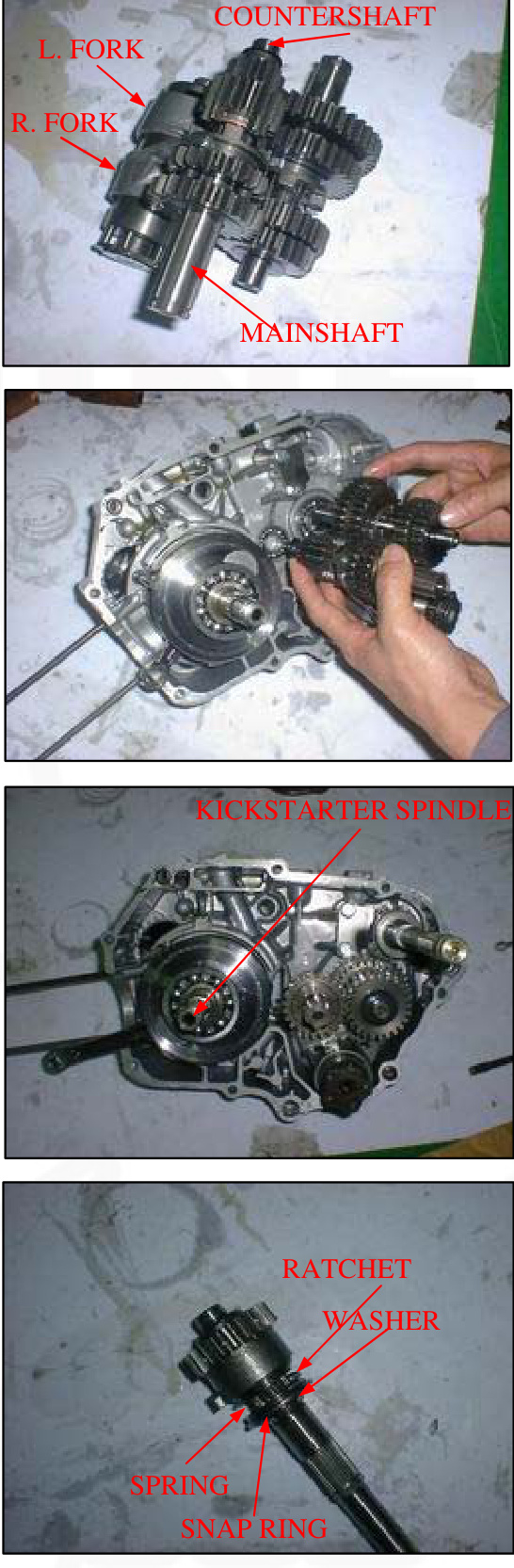

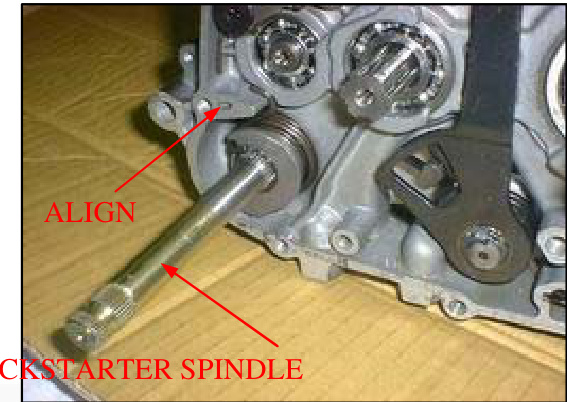

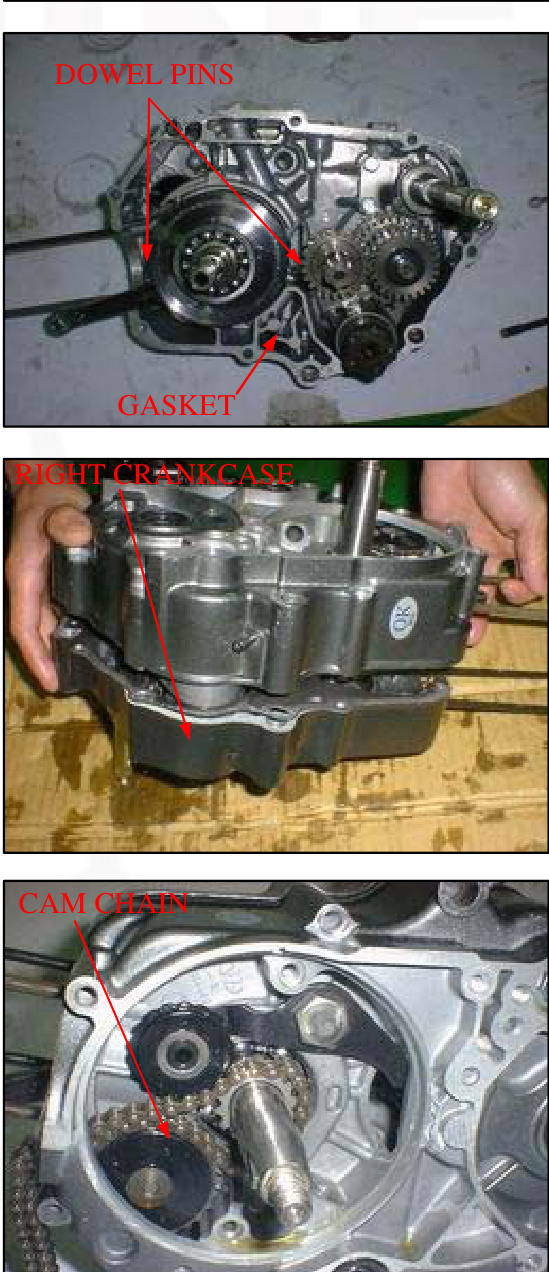

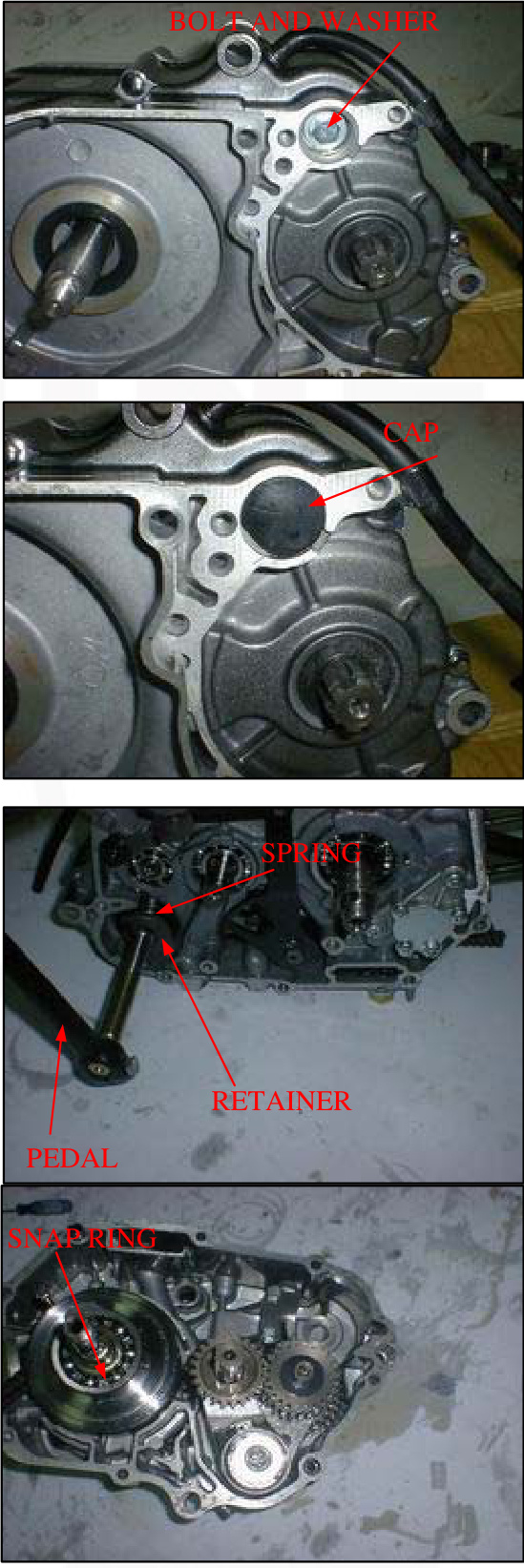

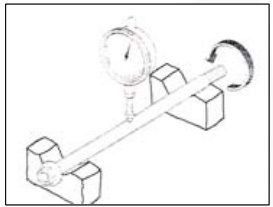

CRANKSHAFT/TRANSMISSION/KICKSTARTER

| ITEM | STANDARD | SERVICE LIMIT |

|---|---|---|

| Crankshaft Side clearance | 0.010-0.350 (0.0004-0.0138) | 0.60 (0.024) |

| Radial clearance | 0-0.012 (0-0.0005) | 0.05 (0.002) |

| Run out | 0.10 (0.004) | |

| Gear I.D. | ||

| M2 | 17.016-17.043 (0.6699-0.6710) | 17.10 (0.673) |

| C1 | 23.020-23.053 (0.9063-0.9076) | 23.10 (0.909) |

| C3 | 20.020-20.053 (0.7882-0.7895) | 20.10 (0.791) |

| Transmission | ||

| :---: | :---: | :---: |

| Bushing I.D. | C1 | 20.000-20.021 (0.7874-0.7882) |

| Gear-to-bushing clearance | C1 | 0.020-0.074 (0.0008-0.0029) |

| Mainshaft O.D. | M2 | 16.966-16.984 (0.6680-0.6687) |

| Countershaft O.D. | C1 | 19.959-19.980 (0.7858-0.7866) |

| Gear-to-shaft clearance | M2 | 0.032-0.077 (0.0013-0.0030) |

| Gear bushing-to-shaft clear | C1 | 0.020-0.062 (0.008-0.0024) |

| Shift fork | ||

| 1.D | 34.075-34.100 (1.3415-1.3425) | |

| Claw thickness | 4.86-4.94 (0.191-0.194) | |

| Shift drum O.D. | 33.950-33.975 (1.3366-1.3376) | |

| 33.93 (1.336) |

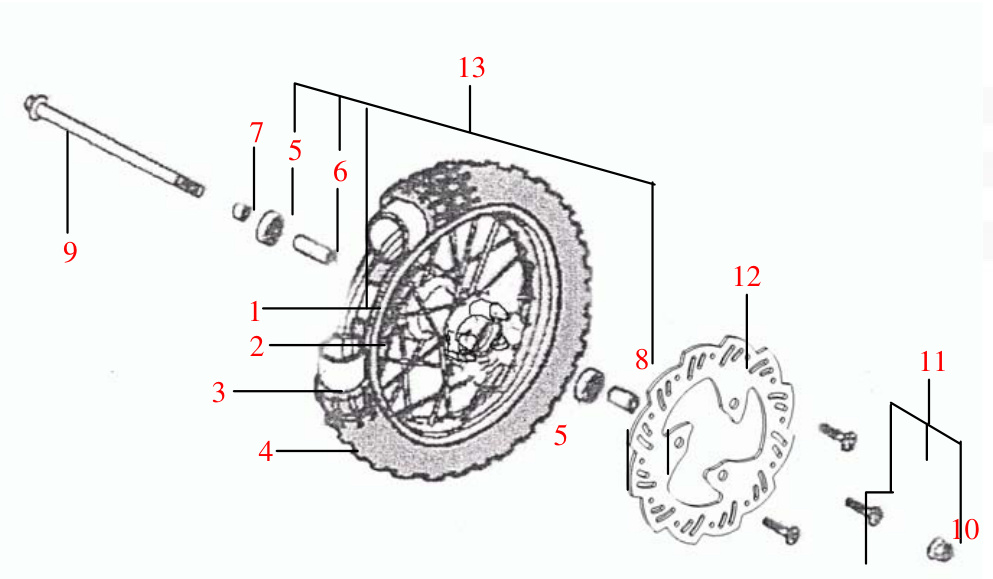

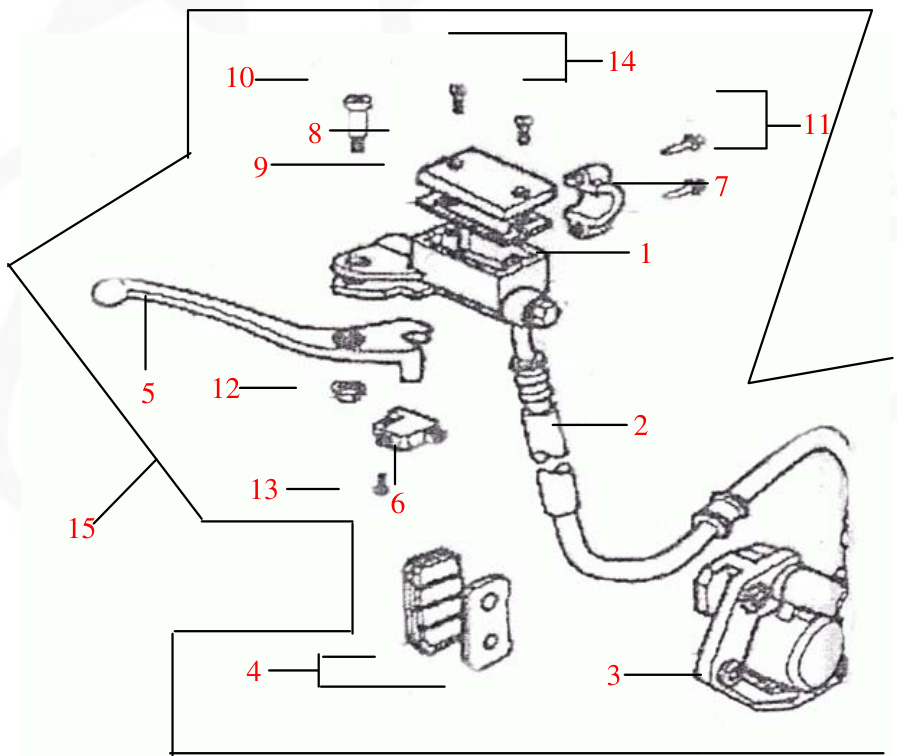

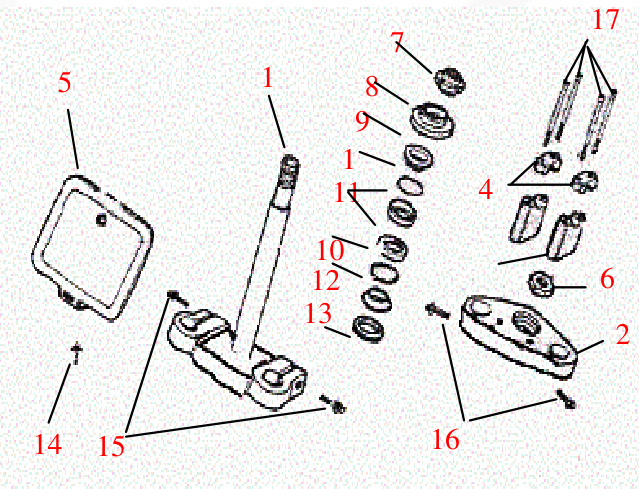

FRONT WHEEL/BRAKE/SUSPENSION/STEERING

| ITEM | STANDARD | SERVICE LIMIT |

|---|---|---|

| Minimum tyre tread depth 175kpa (1.75kgf/cm^2 26.25psi) 3.0 | 0.12 | |

| Cold tyre pressure | ||

| Axle runout Wheel rim rlRadial | 0.20 (0.008) |

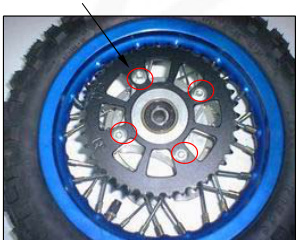

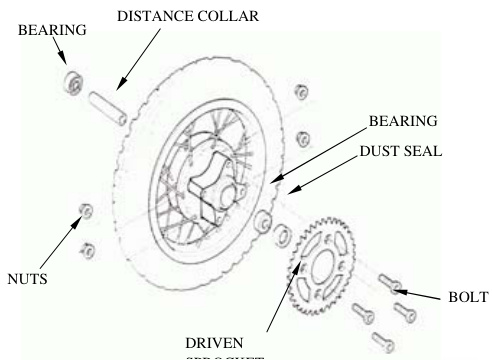

REAR WHEEL/BRAKE/SUSPENSION

| ITEM | Minimum tyre tread depth |

| STANDARD | 175kpa(1.75kgf/cm^2,29.25psi) |

| SERVICE LIMIT | 3.0(0.12) |

| Cold tyre pressure Axle run out | |

| Wheel rim run out Radial Axial | 2.0(0.08) |

| Drive chain Brake | DID420MBK1/88 |

| Slack | Size/Link 15-25(9/16-1) |

| 10-20(3/8-13/16) | |

| Brake pedal free play | |

| ITEM | |

| Spark plug Standard | CR6HSA(NGK) |

| For cold climate/below 41oF/5oC | |

| For extended high speed riding | |

| Spark plug gap | 0.60-0.70mm(0.024-0.028in) |

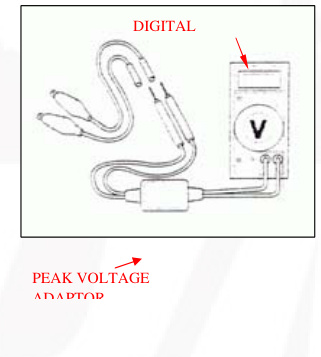

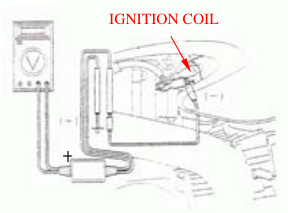

| Ignition coil peak voltage | 100V minimum |

| Ignition coil generator peak voltage Alternator exciter coil peak voltage | 0.7V minimum |

| 100V minimum 15BTDC at idle | |

| Ignition timing("F"mark) |

| FASTENER TYPE | TORQUE N.m(kgf:m, lb. ft) |

|---|---|

| 5mm hex bolt and nut | 5(0.5,3.6) |

| 6mm hex bolt and nut | 10(1.0,7) |

| 8mm hex bolt and nut | 22(2.2,16) |

| 10mm hex bolt and nut | 34(3.5,25) |

| 12mm hex bolt and nut | 54(5.5,40) |

Torque specifications listed below are for important fasteners. Others should be tightened to standard torque values listed above.

NOTES:

- Apply oil to the threads.

- Apply grease to the seating surface.

- U-nut.

- ALOC bolt; replace with a new one.

| ENGINE | ITEM | QTY | THREAD DIAMETER (mm) | TORQUE N.m (kgf-m, lb. ft) | REMARKS |

|---|---|---|---|---|---|

| MAINTENANCE: | NOTE 1 | ||||

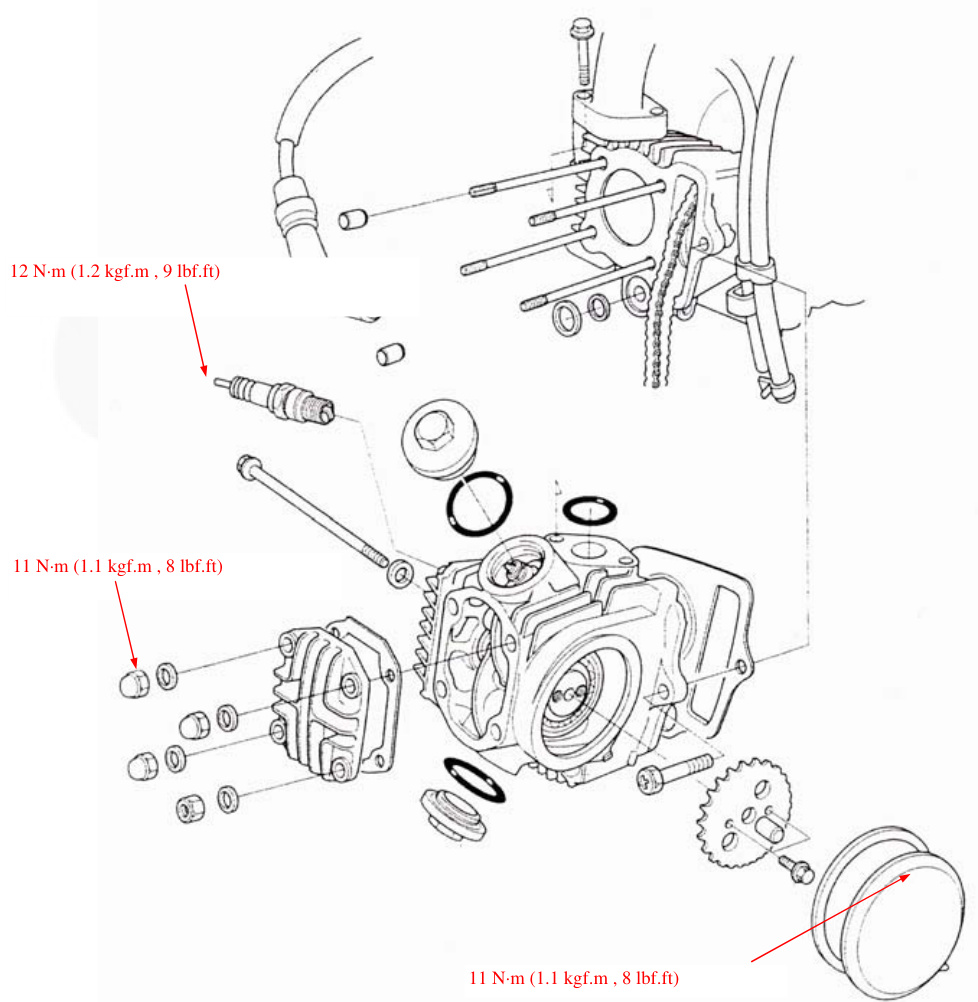

| Spark plug | 1 | 10 | 12 (1.2, 9) | ||

| Oil drain bolt | 1 | 12 | 25 (2.5, 18) | ||

| Valve adjuster hole cap | 2 | 30 | 12 (1.2, 9) | ||

| Valve adjuster locknut | 2 | 5 | 9 (0.9, 6.5) | ||

| Clutch adjuster lock nut | 1 | 8 | 12 (1.2, 9) | ||

| LUBRICATION SYSTEM: | |||||

| Oil pump mounting screw | 3 | 6 | 8 (0.8, 5.8) | ||

| Oil pump cover screw | 3 | 5 | 5 (0.5, 3.6) | ||

| ENGINE REMOVAL/INSTALLATION: | |||||

| Drive sprocket fixing plate bolt | 2 | 6 | 12 (1.2, 9) | ||

| CYLINDER HEAD/VALVES: | |||||

| Cylinder head nut | 4 | 6 | 11 (1.1, 8) | ||

| Cylinder head right side cover | |||||

| --- | --- | --- | --- | --- | --- |

| Cam sprocket bolt | 2 | 5 | 9 (0.9, 6.5) | ||

| CYLINDER/PISTON: | |||||

| Cam chain guide roller pin bolt | 1 | 8 | 10 (1.0, 7) | ||

| CLUTCH/GEARSHIFT LINKAGE: | |||||

| Clutch outer cover screw | 4 | 5 | 5 (0.5, 3.6) | ||

| Clutch lock nut | 4 | 42 (4.3, 31) | |||

| Clutch assembly screw | 5 | 6 (0.6, 4.3) | |||

| Shift drum stopper arm bolt | 1 | 6 | 13 (1.3, 9) | ||

| Shift return spring pin | 1 | 8 | 29 (3.0, 22) | ||

| Gearshift cam bolt | 1 | 6 | 17 (1.7, 12) | ||

| ALTERNATOR/CAM CHAIN TENSIONER | |||||

| Flywheel nut | 1 | 10 | 41 (4.2, 30) 23 (2.3, 17) | ||

| Cam chain tensioner sealing bolt | 1 | 14 | |||

| Cam chain tensioner pivot bolt | 8 | 16 (1.6, 12) | |||

| CRANKSHAFT/TRANSMISSION/KICKSTARTER | |||||

| Shift drum bolt | 1 | 6 | 12 (1.2, 9) |

Tools

NOTES:

- Equivalent commercially available in U.S.A.

- Not available in U.S.A.

- Alternative tool

Description

| DESCRIPTION | TOOL NUMBER | REMARKS | REF.SEC |

|---|---|---|---|

| Carburetor float level gauge | 07401-0010000 | 5 | |

| Spoke wrench, 4.1x4.5mm | 07701-0020100 | NOTE1 | 3,1 |

LUBRICATION AND SEAL POINTS - ENGINE

| LOCATION | MATERIAL | REMARKS |

|---|---|---|

| Cylinder head cover breather | Molybdenum disulfide grease |

| Component | Lubric| Lubrication Point | Lubrication Method 1 | Lubrication Method 2 | |---|---|---| | Valve adjuster hole cap | Threads | Engine oil Pour 1-2cm3 | | Connecting rod small end | Bearing connecting rod small end inner surface Piston outer surface, piston pin hole and ring grooves | Piston pin outer surface | | Camshaft lobes | Cam chain Cam chain guide roller inner surface | Rocker arm inner and slipper surfaces | | Cam chain tensioner push rod (inside) | Fill with 0.5-1cm3 | Fill with 1-2cm3 (page 10-6) | | Oil pump rotors | | | | Clutch center guide | Whole surfaces | | | Clutch discs | | | | Primary drive gear teeth | Inner surface | | | Primary driven gear teeth | | | | Mainshaft sliding surface | | | | Countershaft sliding surface | | | | Transmission gear sliding surface, gear teeth and shifter groove | | |

| Shift drum outer surface | |

| Kickstarter spindle sliding surface | |

| Other rotating and sliding area | |

| Each bearing rotating area | |

| Each oil seal lips | |

| Each O-ring |

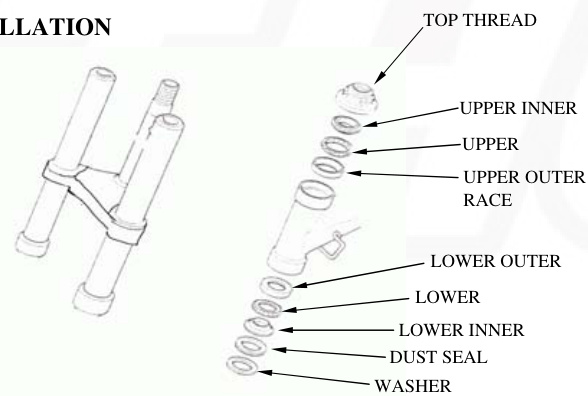

FRAME

| LOCATION | MATERIAL REMARKS |

|---|---|

| Air cleaner housing cover mating groove | Multi-purpose grease |

| Throttle grip pipe flange | |

| Steering head bearing and race sliding surface | |

| Wheel hub dust seal lips | |

| Wheel bearing cavities | |

| Brake panel anchor pin sliding surface | |

| Brake cam spindle and sliding surfaces | |

| Brake pedal pivot | |

| Fork dust seal lips | Apply 5-6g |

| Fork slider outer surface (slider guide sliding surface) | Apply 5-6g |

| Fork slider guide outer groove | |

| Fork spring whole surface | Pack with 14g |

| Swing arm pivot nut seating surface | |

| Side stand pivot and sliding surface | |

| Brake cam dust seal | |

| Throttle cable outer inside | Engine oil |

| Brake cable outer inside | Cable lubricant |

| Handlebar grip rubber inside | |

| Air cleaner connecting tube - housing mati | |

| Ngarea | BondAorequivalent |

Cable & Harness Routing

Emission Control Systems

The California Air Resources Board (CARB) requires manufacturers to certify that their motorcycles comply with applicable exhaust emissions standards during their useful life when operated and maintained according to the instructions provided.

Source of Emissions

Combustion process produces carbon monoxide and hydrocarbons. Controlling hydrocarbon emissions is very important since they react under certain conditions to form photochemical smog when subjected to sunlight. Carbon monoxide does not react in the same manner, but it is toxic. Manufacturer Motor Co. Ltd utilises lean carburettor settings along with other systems to reducing carbon monoxide and hydrocarbons.

Exhaust Emission Control System

The exhaust emission control system comprises a lean carburettor setting, with no adjustments to be made except the idle speed adjustment with the throttle stop screw. This emission control system is distinct from the crankcase emission control system.

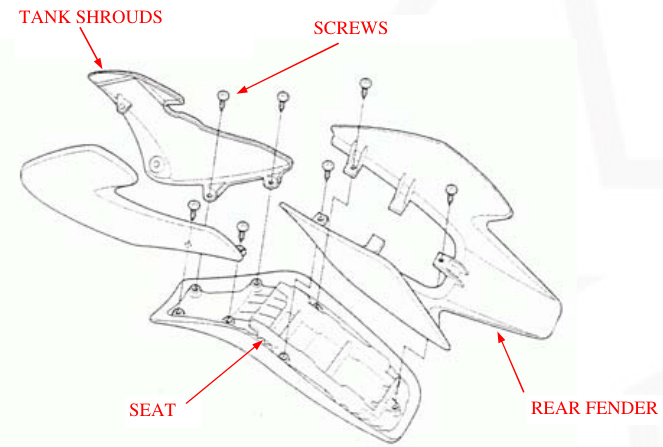

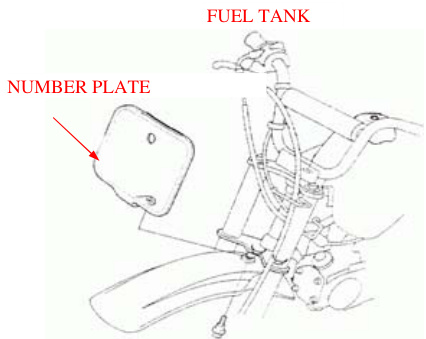

Frame/Body Panels/Exhaust System

| Service Information | Numberplate |

|---|---|

| Troubleshooting | Front Fender |

| Seat | Exhaust System |

| Fuel Tank | Sidestand |

Service Information Warning

Gasoline is highly flammable and can be explosive under certain conditions. Keep out of children's reach. Serious burns could occur if the exhaust system is not cooled down properly before servicing or removing components.

Work in a well-ventilated area. Smoking or allowing sparks or flames in the work area or where gasoline is stored can ignite a fire or explosion.

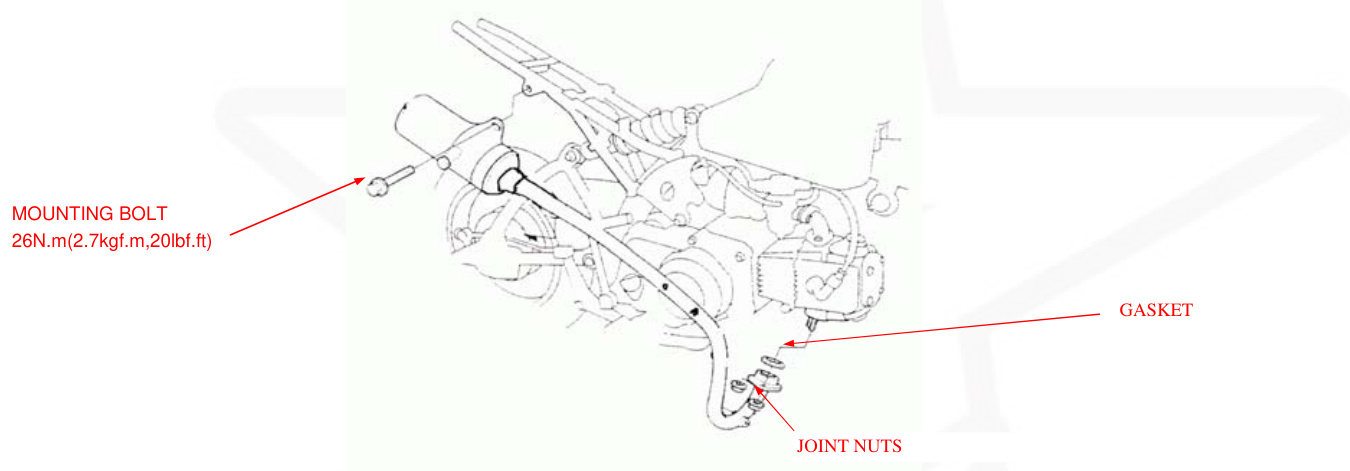

This section addresses the removal and installation of the body panels, fuel tank and exhaust system. After removing the exhaust system from the engine, always replace the exhaust pipe gasket.

For exhaust system installation, loosely fit all the fasteners. Always tighten the exhaust pipe joint nuts first, followed by the mounting. If you first tighten the mounting fasteners, the exhaust pipe may not seat properly.

Always check the exhaust system for leaks after installation.

Torque Values

- Side stand pivot bolt see page 2-5

- Muffler mounting bolt 26 N.m (2.7 kgf.m, 20 lbf.ft)

Troubleshooting

Excessive exhaust noise

- Broken exhaust system

- Exhaust gas leak

- Poor performance

- Deformed exhaust system

- Exhaust gas leak

- Clogged muffler

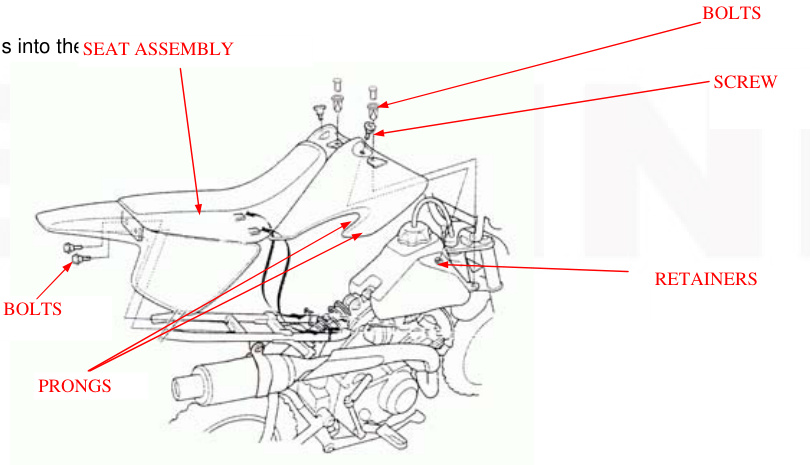

Seat Removal

- Remove the two bolts.

- Remove the two screws and bolts.

- Pull the seat.# Assembly Back and Remove it

INSTALLATION

- Install the seat assembly by inserting the prongs into the SEAT ASSEMBLY retainers on the frame.

- Install the bolts and screws and tighten them.

- Install the bolts and lock them by pushing the center pin flush.

DISASSEMBLY / ASSEMBLY

FRONT FENDER

Remove the three bolts and the front fender. Installation is in the reverse order of removal.

EXHAUST SYSTEM

WARNING

Serious burns may result if the exhaust system is not allowed to cool before components are removed or serviced.

REMOVAL / INSTALLATION

- Remove the seat assembly (page 2-2).

- Remove the exhaust pipe joint nuts.

- Remove the mounting bolt and the muffler.

- Remove the exhaust pipe joint gasket.

For spark arrester maintenance, refer to page 3-17.

Install a new joint gasket into the exhaust port. Set the exhaust pipe onto the engine by aligning the exhaust pipe flange with the cylinder head studs, then install the joint nuts and the mounting bolt.

Tighten the joint nuts.

Tighten the mounting bolt.

TORQUE: 26N.m (2.7kgf.m, 20lbf.ft).

Install the seat assembly (page 2-2).

FRAME / BODY PANELS / EXHAUST SYSTEM

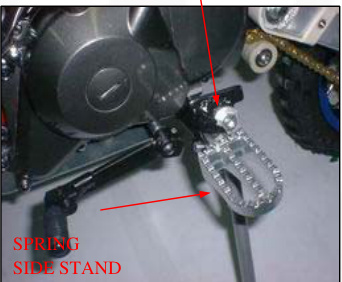

SIDE STAND

REMOVAL

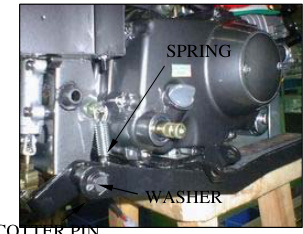

Support the motorcycle securely with a hoist or equivalent. Retract the side stand and remove the following:

- Return spring

- Pivot nut

- Pivot bolt

- Side stand

INSTALLATION

Apply grease to the side stand pivot and sliding surfaces. Install the side stand with the pivot bolt.

Tighten the pivot bolt.

TORQUE: 10N.m (1.0kgf.m, 7lbf.ft)

Loosen the pivot bolt 45-90. Install the pivot nut and tighten it while holding the pivot bolt.

Install the return spring as shown.

Check the side stand operation for freedom of movement.

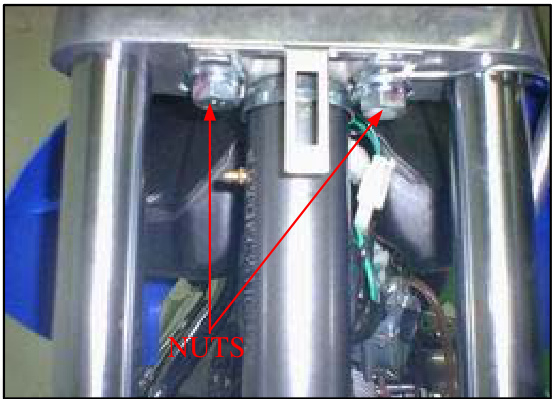

NUT AND BOLT

MAINTENANCE

SERVICE INFORMATION

| ITEM | SPECIFICATIONS |

|---|---|

| Sparkplug | |

| Standard | CR6HSA(NGK) |

| U20FSR-U(DENSO) | |

| For cold climate/below 41F/5C | CR5HSA(NGK) |

| U16FSR-U(DENSO) | |

| For extended high-speed riding | CR7HSA(NGK) |

| U22FSR-U(DENSO) |

WARNING

Gasoline iIt's extremely flammable and is explosive under certain conditions. Work in a well-ventilated area. Smoking or allowing flames or sparks in the work area or where the gasoline is stored can cause a fire or explosion.

When the engine must be running to do some work, make sure the area is well ventilated. Never run the engine in an enclosed area. The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead to death. Run the engine in an open area or with an exhaust evacuation system in an enclosed area.

Place the motorcycle on level ground before starting any work.

SPECIFICATIONS

| Item | Specifications |

|---|---|

| Sparkplug | |

| Standard | CR6HSA(NGK), U20FSR-U(DENSO) |

| Cold Climate | CR5HSA(NGK), U16FSR-U(DENSO) |

| High-Speed | CR7HSA(NGK), U22FSR-U(DENSO) |

| ITEM | SPECIFICATIONS | ||

|---|---|---|---|

| Engine oil capacity | Atdraining | Atdisassembly | 0.6L(0.6US qt, 0.5lmp qt) 0.8L(0.8US qt, 0.7Imp qt) |

| Recommended Engine oil | MANUFACTURE GN44-stroke oil or equivalent motor oil APL service classification SF or SG | ||

| Engine idle speed | 1,500 ± 100 rpm | Viscosity: SAE 10W-30 | |

| Throttle grip free play | |||

| Valve clearance | IN | 2.0-6.0mm(1/16-1/14 in) | |

| EX | 0.05+0.02mm(0.002+0.001 in) | ||

| Drive chain slack | 15-25mmmm(5/8-1 in) | ||

| Drive chain size/link | DID420MBK1/78 | ||

| Brake lever free play | 10-20mm(3/8-13 13/16 in) | ||

| Brake pedal free play | 10-20mm(3/8-13 13/16 in) | ||

| TORQUE VALUES | |||

| Fuel valve mounting bolt | 9N.m(0.9kgf.m,6.5ibf/ft) | ||

| Spark plug | 12N.m(1.2kgf.m,9ibf.ft) | ||

| Valve adjuster hole cap | 12N.m(1.2kgf.m,9ibf.ft) Apply engine oil to the threads | ||

| Valve adjuster lock nut | 9N.m(0.9kgf.m,6.5ibf.ft), 25N.m | ||

| m(2.5kgf.m,18ibf.ft) | |||

| -------------------- | ---------------------- | ----------------------- | ----------------------------------------------------- |

| Oil drain bolt | |||

| Clutch adjuster lock nut | 12N.m(1.2kgf.m,9ibf.ft) | ||

| Rear axle nut | 47N.m(4.8kgf.m,35ibf.ft) U-nut |

TOOLS

- Valve adjusting wrench, 8x10mm

- Valve adjuster B

- Spoke wrench, 4.1x4.5mm

MAINTENANCE

MAINTENANCE SCHEDULE Perform the PRE-RIDE INSPECTION in the Owner's Manual at each scheduled maintenance period.

- Inspect and Clean, Adjust, Lubricate or replace if necessary. C: Clean R: Replace A: Adjust L: Lubricate

FREQUENCY

Should be serviced by your dealer, unless the owner has proper tools and service data and is mechanically qualified. In the interest of safety, we recommend these items be serviced only by your dealer.

NOTE Service more frequently when ridden in wet or dusty conditions.

FUEL LINE

Check the fuel line for deterioration, damage or leakage. Replace the fuel line if necessary.

FUEL STRAINER SCREEN

WARNING

Gasoline is extremely flammable and is explosive under certain conditions. Work in a well ventilated area. Smoking where the gasoline is stored can cause a fire or explosion. Wipe spilled gasoline at once. Turn the fuel valve OFF.

Disconnect the fuel tube. Place a drain pan under the fuel tube and turn the fuel valve ON to drain the fuel tank.

After the tank has drained completely, remove the two bolts and collars, and remove the fuel valve and strainer screen.

Wash the fuel strainer screen in non-flammable or high flash solvent.

Check the O-ring is in good condition, reinstall the fuel valve.

Tighten the fuel valve mounting bolts to the specified torque.

TORQUE: 9N.m (0.9kgf.m, 6.5lbf.ft) After installation, check for fuel leaks.

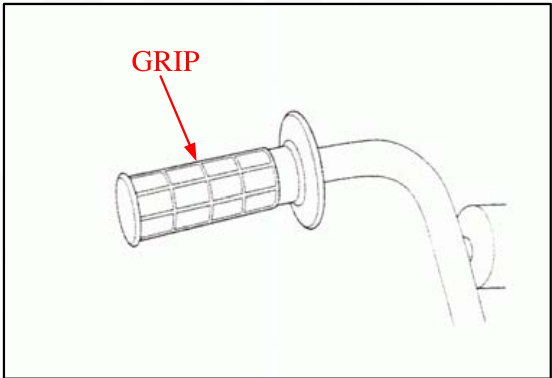

THROTTLE OPERATION

Check for smooth throttle grip full opening and automatic full closing in all steering positions. Check the throttle cable and replace it if it is deteriorated, kinked, or damaged. Lubricate the throttle cable if throttle operation is not smooth. Measure the free play at the throttle grip flange.

FREE PLAY: 2.04.0mm (1/163/16 in)

MAINTENANCE

Throttle grip free play can be adjusted at the upper end of the throttle cable.

Remove the dust cover from the adjuster. Adjust the free play by loosening the lock nut and turning the adjuster. Tighten the lock nut and install the dust cover properly.

Recheck the throttle operation.

AIR FILTER

SPARK PLUG

REMOVAL

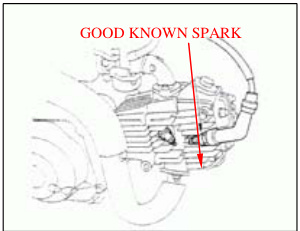

Disconnect the spark plug cap. Remove the spark plug using a spark plug wrench or an equivalent. Inspect or replace as described in the maintenance schedule (page 3-3). Clean around the spark plug base with compressed air before removing and be sure that no Debris is allowed to enter the combustion chamber.

Inspection

Check the following and replace if necessary (recommended spark plug: page 3-1):

- Insulator for damage

- Electrodes for wear

- Burning condition

- Dark to light brown indicates good condition.

- Excessive lightness indicates malfunctioning ignition system or lean mixture.

- Wet or black sooty deposit indicates over-rich mixture

Reusing a Spark Plug

Clean the spark plug electrodes with a wire brush or special plug cleaner. Check the gap between the center and side electrodes with a wire type feeler gauge. If necessary, adjust the gap by bending the side electrode carefully.

Spark plug gap: 0.6-0.7mm (0.024-0.028 in)

Caution

To prevent damage to the cylinder head, hand tighten the spark plug before using a wrench to tighten to the specified torque.

Reinstall the spark plug in the cylinder head and hand tighten, then torque it using a spark plug wrench.

Torque: 12N-m (1.2kgf.m, 9lbf.ft)

Replacing a Spark Plug

Set the plug gap to specification with a wire type feeler gauge (see previous page).

Caution: Do not over-tighten the spark plug.

Install and hand tighten the new spark plug, then tighten it about 1/2 of a turn after the sealing washer contacts the seat of the plug hole.

Install the spark cap.

Valve Clearance Inspection

Remove the valve adjuster hole caps.

Inspect and adjust the valve clearance while the engine is cold (below 95 F/35C).

Remove the left crankcase cover (page10-2).

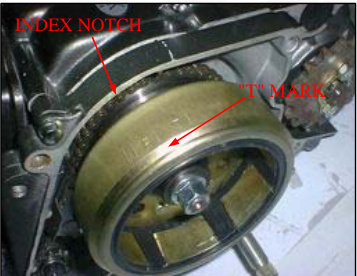

Turn the crankshaft counterclockwise and align the "T" mark on the flywheel with the index notch on the left crankcase. Make sure the piston is at TDC (Top Dead Center) on the compression stroke. This position can be obtained by confirming that there is slack in the rocker arm. If there is no slack, rotate the crankshaft one full turn counterclockwise and match up the "T" mark again.

Maintenance

Check the valve clearance by inserting a feeler gauge between the valve adjusting screw and valve stem. Valve clearance in/ex: 0.05 0.02mm (0.002 0.001in)

Adjustment

Adjust by loosening the lock nut and turning the adjusting screw until there is a slight drag on a feeler gauge. Hold the adjusting screw and tighten the nut.

Tools:

Valve adjusting wrench, 8x9mm 07708-0030100 (equivalent commercially available in U.S.A) 07708-0030400 or 07908-KE90200

Valve adjuster B

Torque: 9.N.m (0.9kgf.m, 6.5lbf.ft)

Recheck the valve clearance.

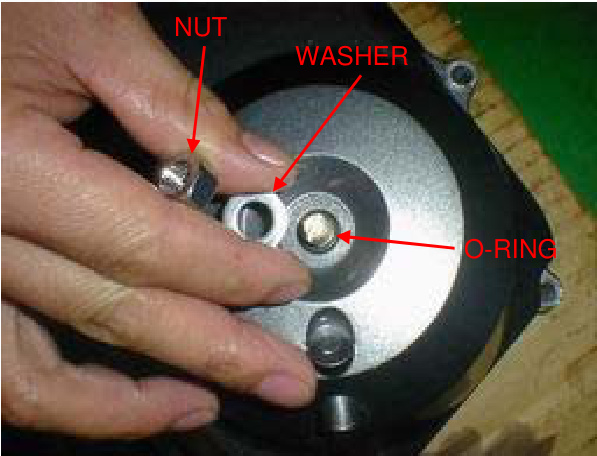

Check the valve adjuster hole cap O-ring is in good condition, replace if necessary. Coat the O-ring with clean engine oil and install them in the valve adjuster hole caps. Apply clean engine oil to the threads. Install and tighten the valve adjuster hole caps to the specified torque.

Torque: 12N.m (1.2kgf-m, 9lb.ft)

Install the left crankcase cover (page 10-8).

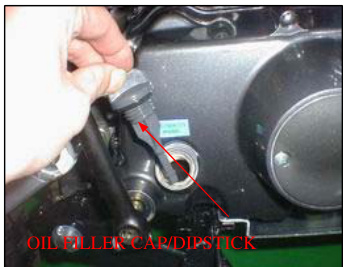

Engine Oil Level Inspection

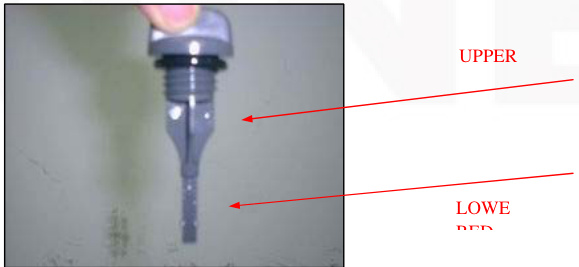

Support the motorcycle in an upright position on level ground. Remove the oil filler cap/dipstick and wipe it clean. Check the oil level by inserting.Place the oil filler cap/dipstick into the oil filler hole without screwing it in.

MAINTENANCE

The engine contains a sufficient amount of oil if the oil level is between the upper and lower level marks on the dipstick. If the level is near or below the lower level mark, fill with the recommended oil up to the upper level mark.

RECOMMENDED ENGINE OIL

4-stroke oil or equivalent motor oil API service classification: SF or SG Viscosity 10W-30

NOTE

Other viscosities shown in the chart may be used when the average temperature in your riding area is within the indicated range. Reinstall the filler cap/dipstick.

ENGINE OIL CHANGE

WARNING

When the engine must be running to do some work, make sure the area is well-ventilated. Never run the engine in an enclosed area.

Exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead to death. Run the engine in an open area or with an exhaust evacuation system in an enclosed area.

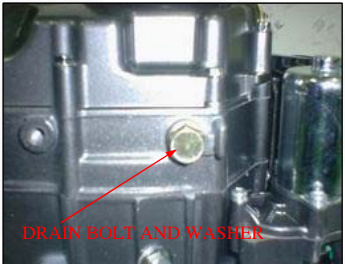

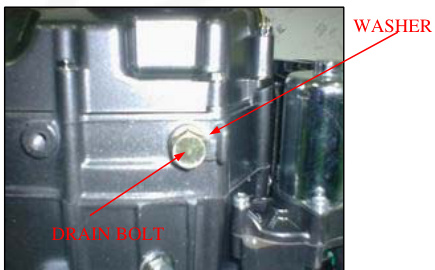

Warm up the engine Stop the engine and remove the oil filler cap/dipstick and drain bolt. Drain the oil completely.

Used oil may cause skin cancer if repeatedly left in contact with the skin for prolonged periods. Although this is unlikely unless you handle used oil on a daily basis. It is still advisable to thoroughly wash your hands with soap and water as soon as possible after handling used oil. KEEP OUT OF REACH OF CHILDREN.

MAINTENANCE

Check that the sealing washer on the drain bolt is in good condition, replace if necessary. Install and tighten the drain bolt.

TORQUE: 25N.m (2.5kgf-m, 18lbf.ft)

Fill the crankcase with recommended engine oil (page 3-8)

OIL CAPACITY

0.6L (0.6USqt, 0.5lmp qt) at draining 0.8L (0.8USqt, 0.7lmp qt) at disassembly

Install the oil filler cap/dipstick

Start the engine and let it idle for 2 to 3 minutes. Stop the engine and recheck the oil level. Make sure there are no oil leaks.

ENGINE OIL STRAINER SCREEN CLEANING

Remove the right crankcase cover (page 9-3)

Remove the oil strainer screen and the sealing rubber Check the screen for damage and the sealing rubber for damage or deterioration.

Reinstall the oil strainer screen and right crankcase cover (page 9-17)

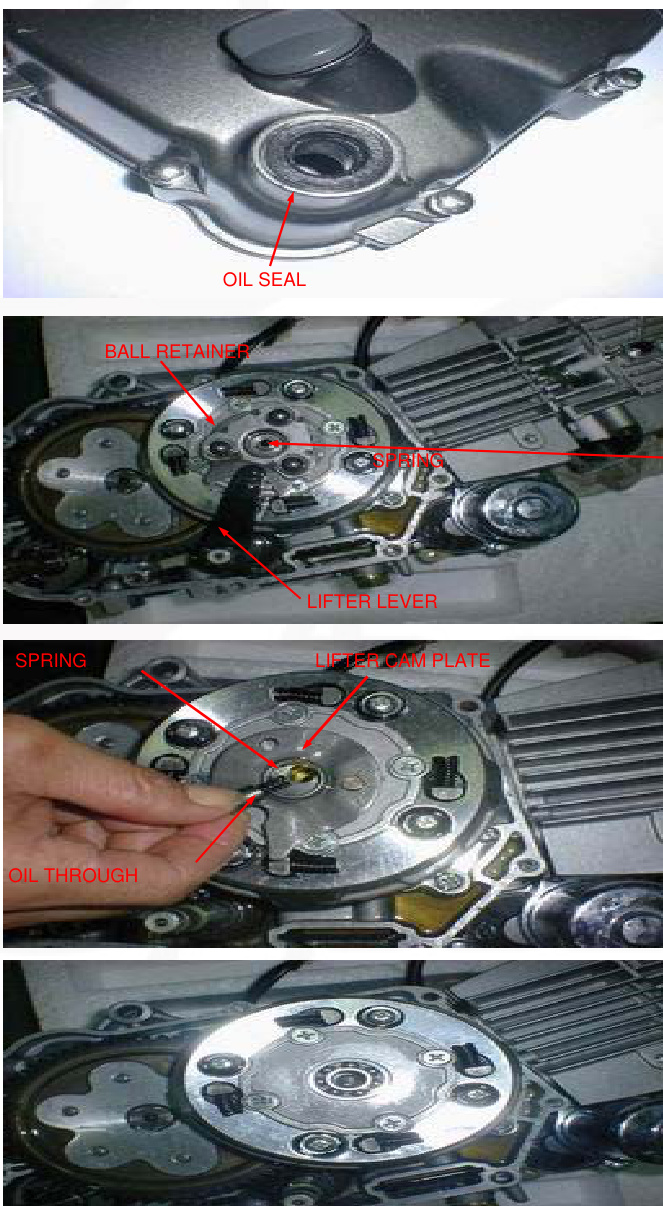

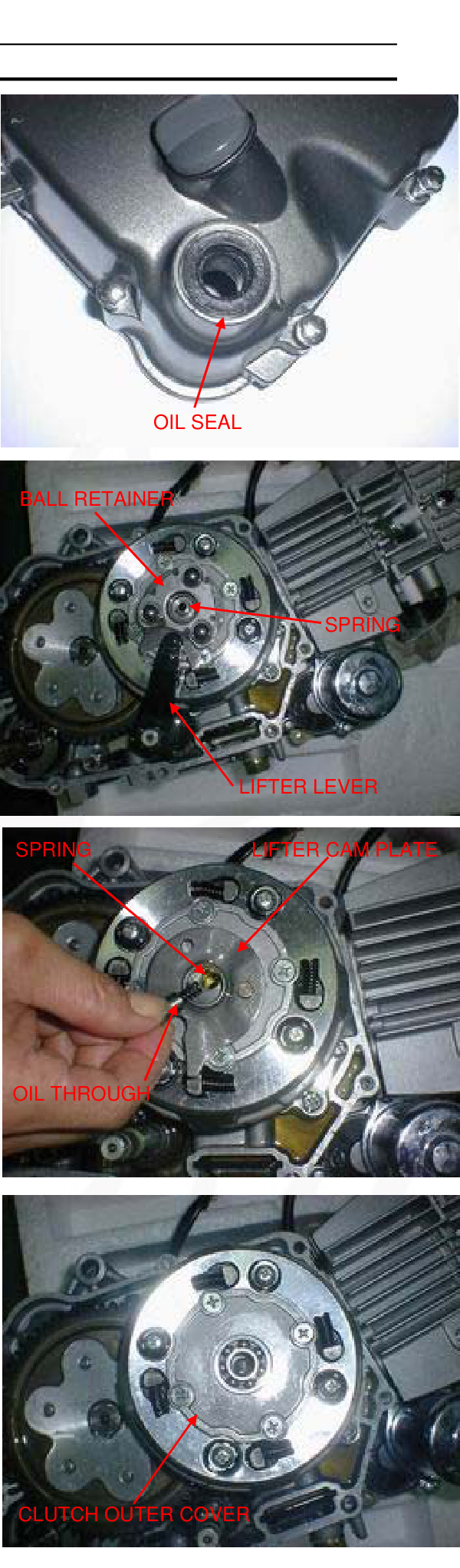

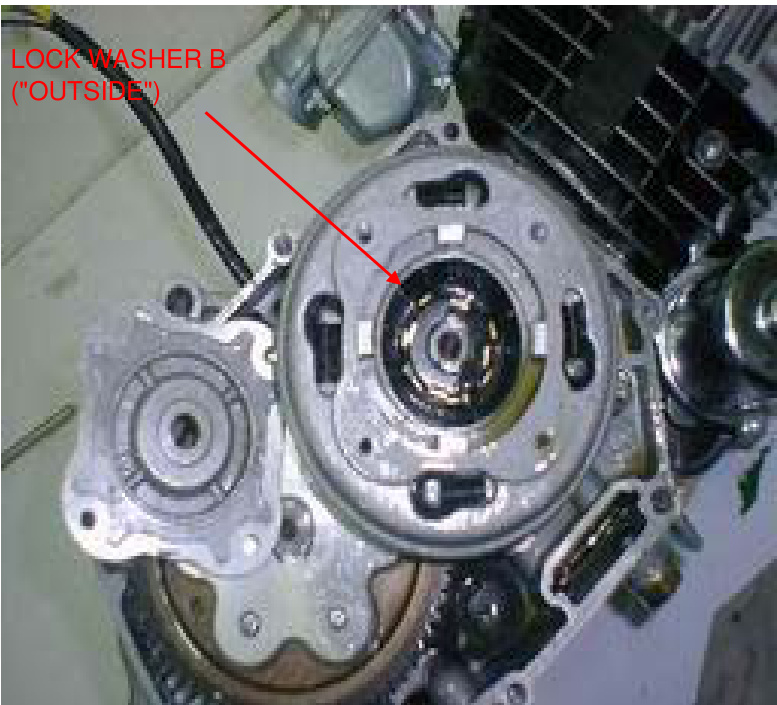

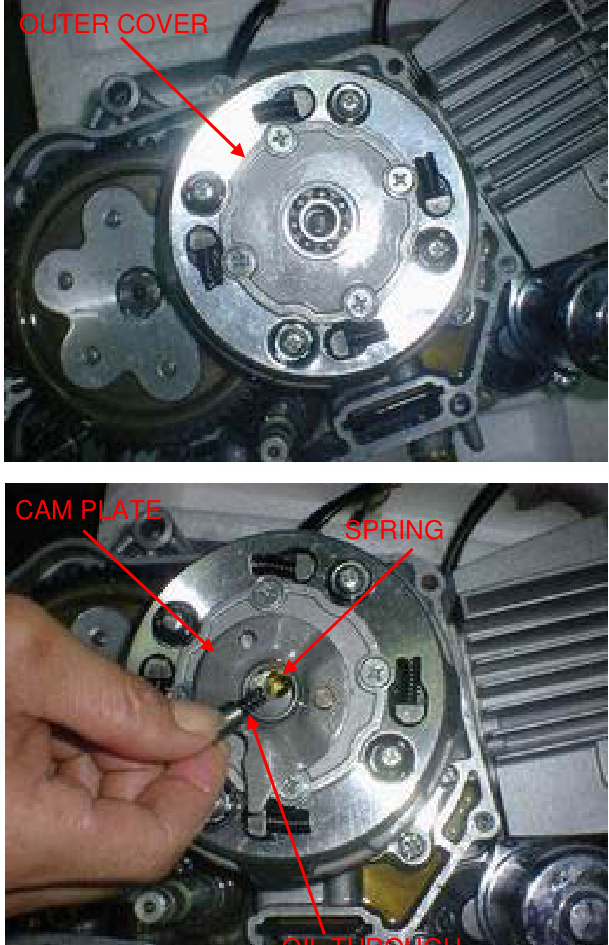

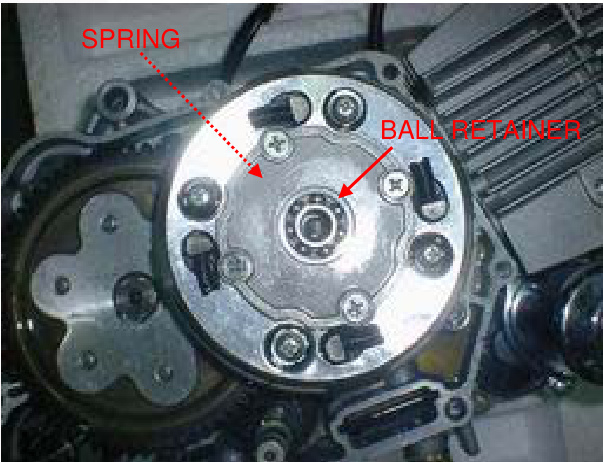

ENGINE OIL CENTRIFUGAL FILTER CLEANING

Remove the right crankcase cover, ball ret# ainer, and clutch lifter lever (page 9-3)

Remove the four screws and clutch outer cover.

MAINTENANCE

Clean the clutch outer cover and in the clutch outer cover using a clean lint-free cloth.

CAUTION

Do not allow dust and dirt to enter the crankshaft oil passage. Do not use compressed air.

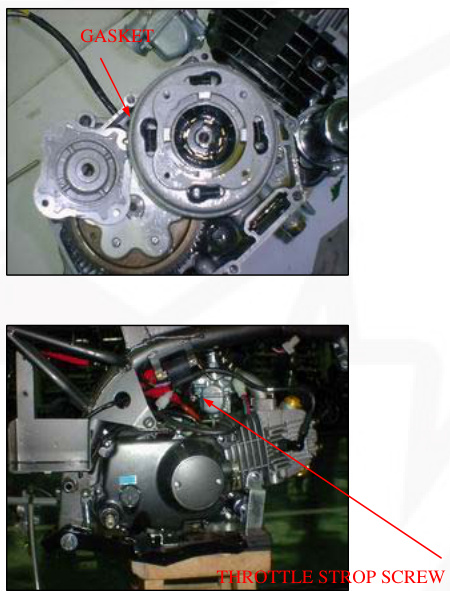

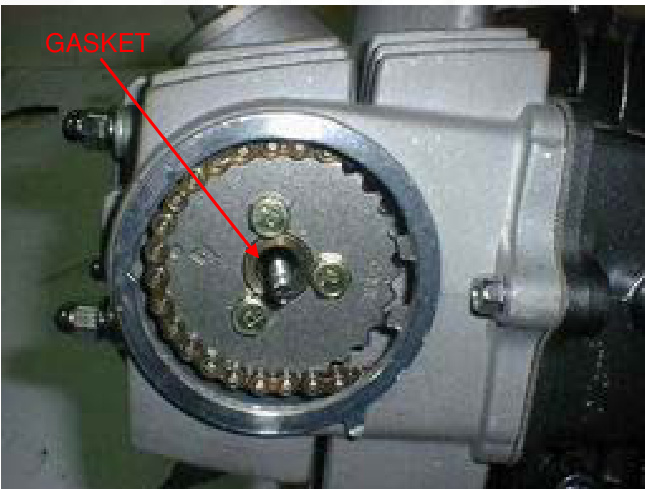

Reinstall the clutch outer cover using a new gasket (page 9-13).

ENGINE IDLE SPEED

WARNING

When the engine must be running to do some work, ensure the area is well-ventilated. Never run the engine in an enclosed area. The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead to death. Run the engine in an open area or with an

Exhaust Evacuation System in an Enclosed Area

Note

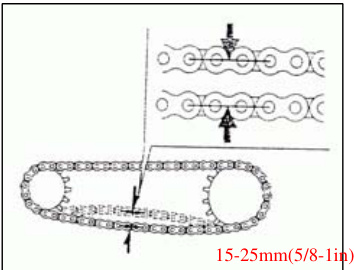

Inspect and adjust the idle speed after all other engine maintenance items have been performed and are within specifications. The engine must be warm for accurate idle speed inspection and adjustment. Warm up the engine for about ten minutes. Connect a tachometer. Turn the throttle stop screw as required to obtain the specified idle speed.

Idle Speed:

- 700 ± 100 rpm

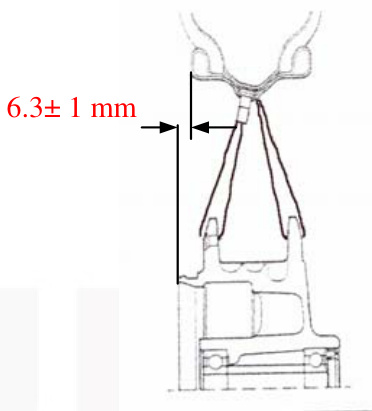

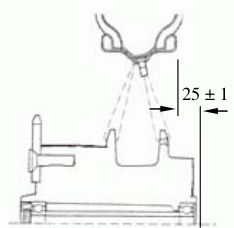

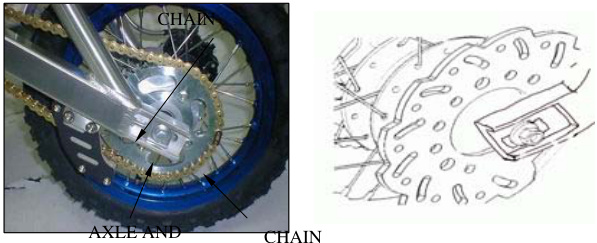

Drive Chain Slack Inspection

Warning

Never inspect and adjust the drive chain while the engine is running.

Turn off the engine, place the motorcycle on its side stand, and shift the transmission into neutral. Check the slack in the lower drive chain midway between the two sprockets.

Chain Slack:

15-25mm (5/8-1in)

Caution

Excessive chain slack, 40mm (1-1/2in) or more, may damage the frame.

Adjustment

Loosen the axle nut. Loosen the adjuster lock nuts and turn both adjusting nuts an equal number of turns until the correct drive chain slack is obtained. Make sure the index marks on both adjusters are aligned with the index lines on the swingarm. Tighten the rear axle nut to the specified torque.

Torque:

47 N.m (4.8 kgf.m, 34 lbf.ft)

Tighten both lock nuts. Recheck the drive chain slack and free wheel rotation. Check the rear brake pedal free play (page 3-15), adjust if necessary. Lubricate the drive chain. Wipe off the excess oil.

Cleaning Inspection and Lubrication

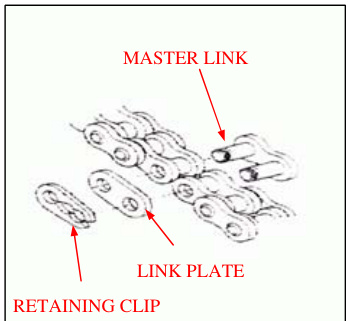

If the drive chain becomes extremely dirty, it should be removed and cleaned prior to lubrication. Carefully remove the retaining clip with pliers. Remove the link plate and then the master link and now the drive chain can be removed from the sprockets.

Maintenance

Clean the chain with non-flammable or high flash point solvent and wipe it dry. Be sure the chain has dried completely before lubricating. Lubricate the drive chain with #80-90 gear oil. Wipe off the excess gear oil.

Inspect the drive chain for possible damage or wear. Replace any chain tThe hat has damaged rollers, loose fitting links, or otherwise appears unserviceable.

Measure the drive chain length between a span of 41 pins (40 links) from pin center to pin center with the chain held taut and any kinked joint straightened.

Service Limit:

511mm (20.1in)

Installing a new chain on badly worn sprockets will cause the new chain to wear quickly. Inspect the teeth on both sprockets for wear or damage. Replace if necessary. Never use a new drive chain on worn sprockets. Both chain and sprockets must be in good condition, or the new replacement parts will wear rapidly.

Install the Drive Chain

- Install the drive chain onto the sprockets.

- Install the master link and link plate.

- Install the retaining clip so that its open end is opposite the normal rotation of the chain.

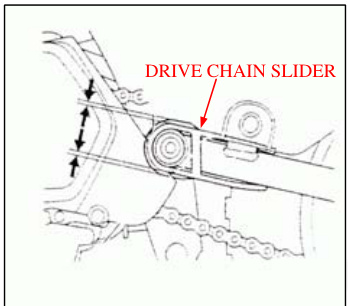

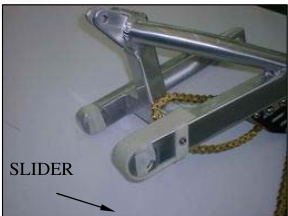

Drive Chain Slider

Check the drive chain slider for wear or damage.

Maintenance

Replace the drive chain slider if the wear limit guide lug is worn out or it has been damaged.

Front Brake

Measure the front brake lever free play at the tip of the lever. FREE PLAY: 10-20mm (3/8-13/16 in).

Rear Brake

Check the brake pedal free play. FREE PLAY: 10-20mm (3/8-13/16 in).

Adjust the brake pedal free play by turning the adjusting nut. Make sure the cutout on the adjusting nut is seated on the joint pin.

Clutch System

If the clutch does not operate properly, adjust by doing the following: Loosen the clutch adjuster lock nut and turn the adjusting bolt one full turn counterclockwise.

Side Stand

Support the motorcycle on a level surface. Check the side stand spring for damage or loss of tension. Check the side stand assembly for freedom of movement and lubricate the side stand pivot if necessary.

Suspension Warning

Loose, worn, or damaged suspension parts impair motorcycle stability and control. Repair or replace any damaged components before riding. Riding a motorcycle with faulty suspension increases your risk of an accident and possible injury.

Front Suspension Inspection

Refer to section 12 for fork service.

Maintenance

Rear Suspension Inspection

Support the motorcycle on a safety stand or box and raise the rear wheel off the ground. Hold the swingarm and move the rear wheel sideways with force to see if the wheel bearings are worn. Check for worn or loose suspension pivot components by grabbing the swingarm and attempting to move the swingarm side to side. Check each fastener on the swingarm and shock absorber, if any looseness is noted. Check the action of the shock absorber by compressing it several times. Check the entire shock absorber assembly for signs of leaks, damage, or loose fasteners. Replace damaged components which cannot be repaired. Tighten all nuts and bolts. Refer to se# Section 13 for Shock Absorber and Swingarm Service.

MAINTENANCE

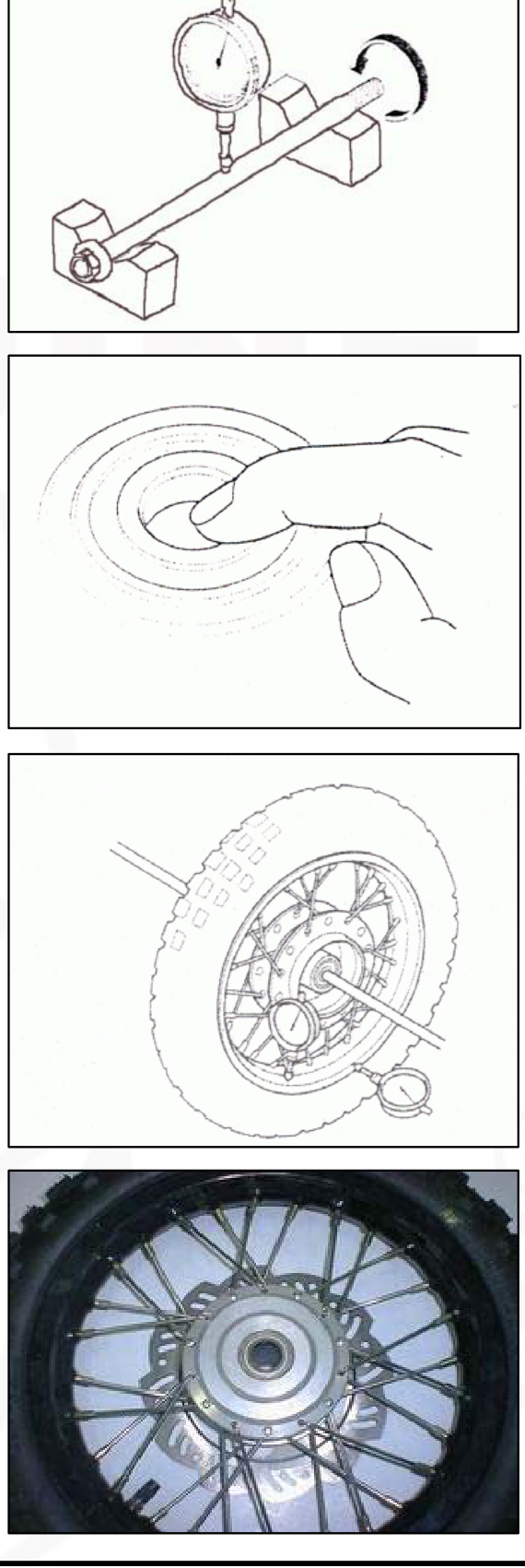

Wheels/Tyres Recommended Tyre Pressure and Tyre Size

| Front | Rear | ||

|---|---|---|---|

| Tyre Pressure kPa (kgf/cm2, psi) | 175(1.75,15) | 175(1.75,18) |

Tyre pressure should be checked when the tyres are cold. Check the tyres for cuts, embedded nails, or other damage. Check the front and rear wheel for trueness (refer to section 12 and 13). Measure the tread depth at the center of the tyres. Replace the tyres when the tread depth reaches the following limits. Minimum tread depth: Front/Rear: 3.0mm (0.12in).

Tool: Spoke Wrench, 4.1*4.5 mm 07701-0020100

Steering Head Bearings

Support the motorcycle securely and raise the front wheel off the ground. Check that the handlebar moves freely from side to side. If the handlebar moves unevenly, binds, or has vertical movement, inspect the steering head bearing (pages 12-15). Check that the control cables do not interfere with handlebar rotation.

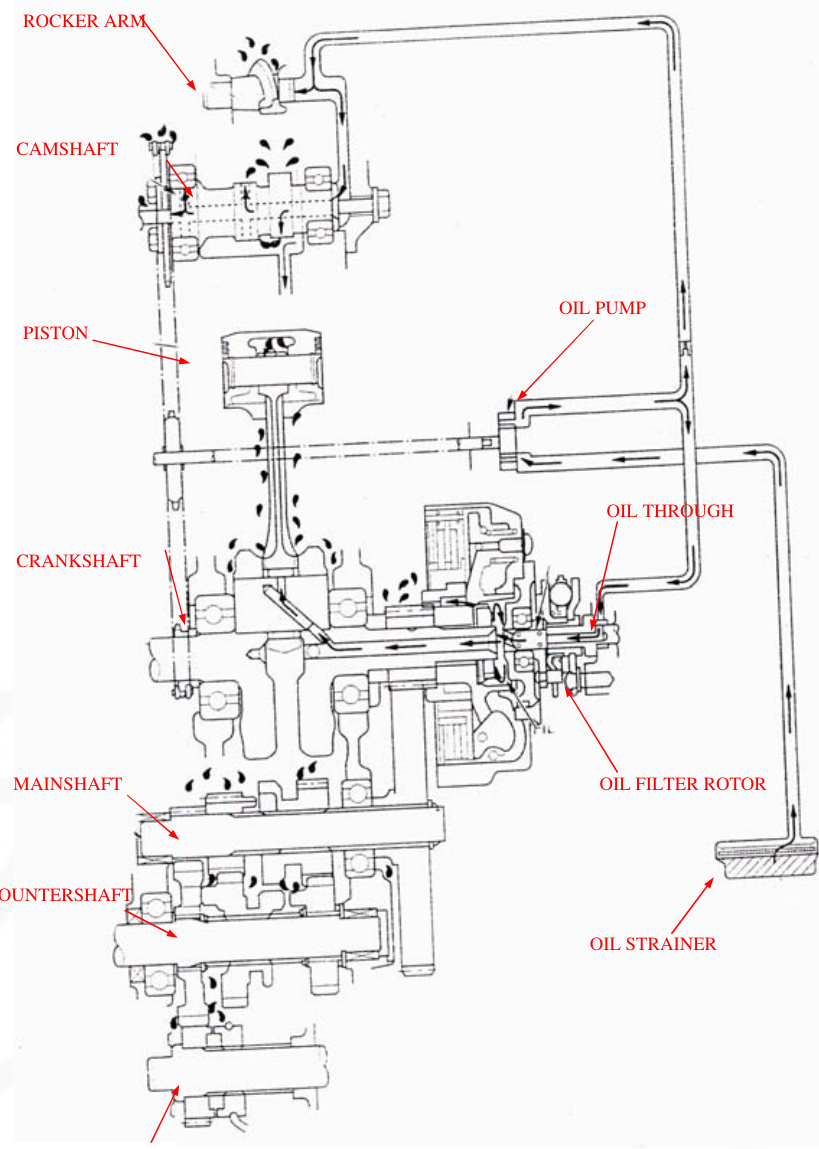

Lubrication System Diagram

| Lubrication System Diagram | Troubleshooting |

|---|---|

| Service Information | Oil Pump |

When the engine must be running to do some work, make sure the area is well-ventilated. Never run the engine in an enclosed area. The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead to death. Run the engine in an open area or with an exhaust evacuation system in an enclosed area. Used engine oil may cause skin cancer if repeatedly left in contact with the skin for prolonged periods. Although this is unlikely unless you handle used oil on a daily basis, it is still advisable to thoroughly wash your hands with soap and water as soon as possible after handling used oil. Keep out of reach of children.

The oil pump can be serviced with the engine installed in the frame. The service procedures in this section must be performed with the engine oil drained. If any portion of the oil pump is worn beyond the specified service limits, replace the oil pump as an assembly. After the oil pump has been installed, check that there are no oil leaks.

Specifications

| Item | Standard | Service Limit |

|---|---|---|

| Engine oil capacity |

Troubleshooting

Engine oil level too low or high oil consumption

- Oil contamination

- Normal oil consumption

- External oil leak

- Worn piston ring or incorrect piston ring installation

- Worn cylinder

- Worn valve guide or stem seal

- Oil pump worn or damaged

- Oil not changed often enough

- Worn piston ring or incorrect piston ring installation

- Worn valve guide or stem seal

- Clogged oil strainer screen

LUBRICATION SYSTEM

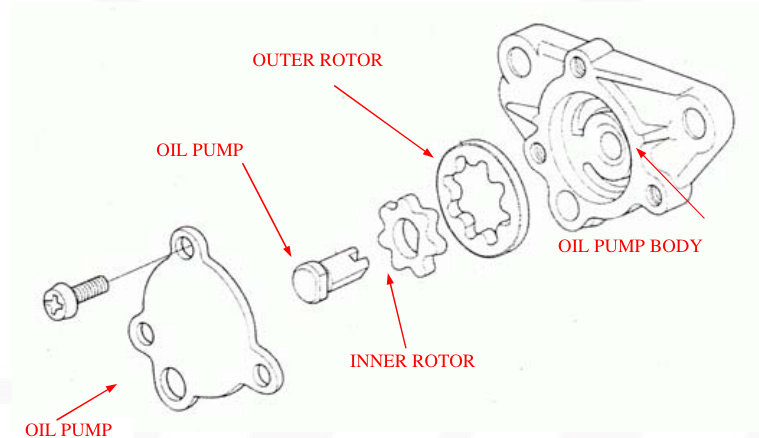

OIL PUMP

REMOVAL

Remove the clutch assembly (page 9-4)

When the oil pump is ready to be disassembled, loosen the pump cover screws. Remove the three screws and oil pump assembly.

DISASSEMBLY

Remove the three screws and oil pump cover. Remove the oil pump shaft, then remove the inner and outer rotors from the oil pump body.

INSPECTION

Temporarily install the outer and inner rotors into the oil pump body.

Install the oil pump shaft.

Measure the tip clearance between the inner and outer rotors.

If any portion of the oil pump is worn beyond the specified service limit, replace the oil pump as an assembly.

SERVICE LIMIT: 0.20mm (0.008in)

Measure the pump body clearance between the outer rotor and pump body.

SERVICE LIMIT: 0.12mm (0.005in)

ASSEMBLY

Install the inner and outer rotors into the oil pump body. Install the oil pump shaft aligning the flat surfaces of the shaft and inner rotor. Fill the oil pump with 0.5-1cm3 of engine oil.

Install the oil pump cover and tighten the screws to the specified torque. TORQUE: 5N.m (0.5kgf.m, 3.6lbf.ft)

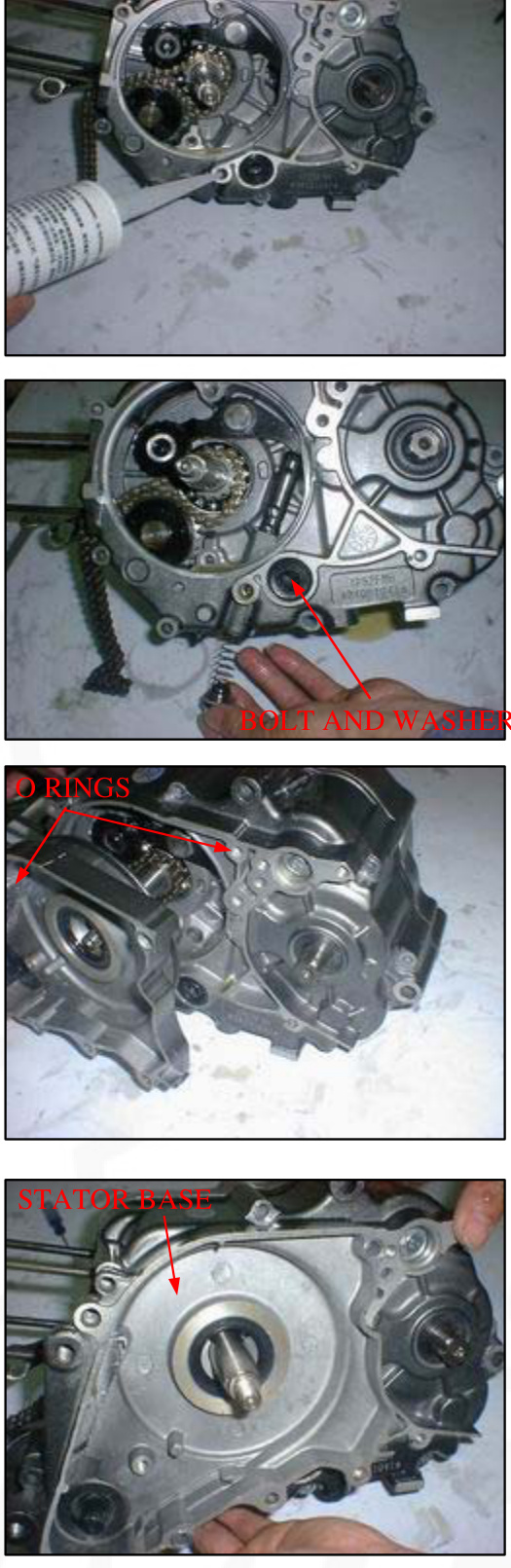

INSTALLATION

Install the rotor shaft collar into the crankcase. Install a new gasket onto the oil pump body.

Install the oil pump into the crankcase while aligning the pump shaft groove with the cam chain guide spindle lug.

Install and tighten the three screws to the specified torque.

TORQUE: 8N.m (0.8kgf.m, 5.8ibf.ft)

Install the clutch assembly (page 9-12)

5. Fuel System

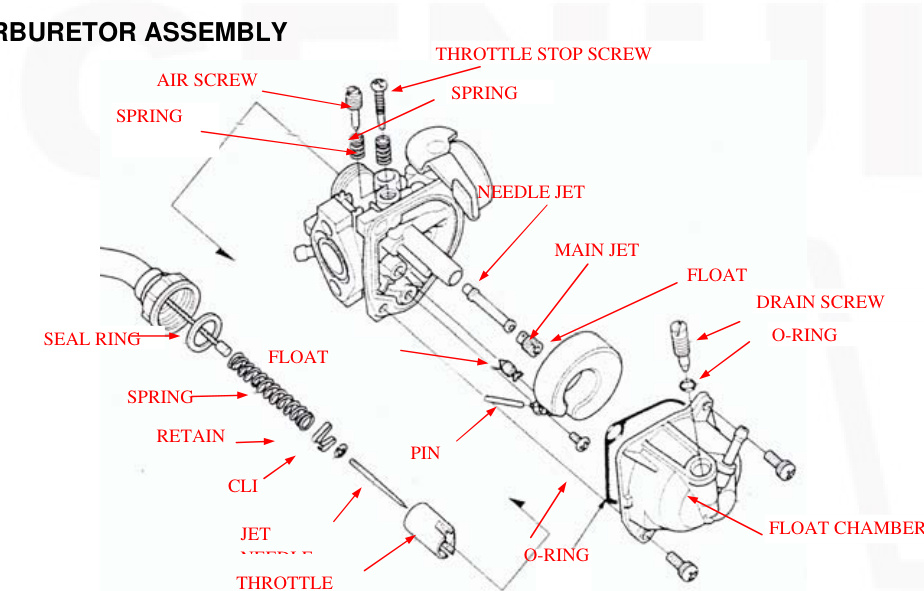

| SERVICE INFORMATION | CARBURETOR ASSEMBLY |

|---|---|

| TROUBLESHOOTING | CARBURETOR INSTALLATION |

| AIR CLEANER HOUSING | AIR SCREW ADJUSTMENT |

| CARBURETOR REMOVAL | CRANKCASE BREATHER |

| CARBURETOR DISASSEMBLY |

Service Information

General

WARNING

Gasoline is extremely flammable and is explosive under certain conditions. KEEP OUT OF REACH OF CHILDREN. Bending or twisting the control cable will impair smooth operation and could cause the cable to stick or bind resulting in loss of vehicle control.

Work in a well-ventilated area. Smoking or allowing flames or sparks in the work area or where gasoline is stored can cause a fire or explosion.

Refer to section 2 for fuel tank removal and in# Installation

When disassembling fuel system parts, note the location of the O-ring. Replace them with new ones on reassembly. Before disassembling the carburetor, place a suitable container under the carburetor drain tube. Loosen the screw and drain the carburetor.

After removing the carburetor, wrap the intake port of the engine with a towel or cover it to prevent any foreign material from dropping into the engine.

Note

If the vehicle is to be stored for more than one month, drain the float bowl. Fuel left in the float bowl may cause clogged jets, resulting in hard starting or poor drivability.

Troubleshooting

-

Engine will not start

- Too much fuel getting to the engine

- Air cleaner clogged

- Flooded carburetor

- Intake air leak

- Fuel contaminated or deteriorated

- No fuel to carburetor

- Fuel strainer clogged

- Fuel tube clogged

- Float level maladjusted

- Fuel tank breather tube clogged

- Too much fuel getting to the engine

-

Engine stall, hard to start, rough idling

- Fuel line restricted

- Ignition malfunction

- Fuel mixture too lean or too rich

- Fuel contaminated or deteriorated

- Idle speed maladjusted

- Float level maladjusted

- Fuel tank breather tube clogged

- Air screw maladjusted

- Slow circuit clogged

Lean Mixture

- Fuel jets clogged

- Float valve faulty

- Float level too low

- Fuel line restricted

- Carburetor air vent tube clogged

- Intake air leak

- Throttle valve faulty

Rich Mixture

- Choke lever in CLOSED position

- Float valve faulty

- Float level too high

- Air jets clogged

- Air

Fuel System

Air Cleaner Housing

Removal and Installation

NOTE: Refer to page 3-5 for air cleaner element service

Loosen the connection tube band screw. Remove the bolt and the air cleaner housing assembly.

Tubes

Installation is in the reverse order of removal. At installation secure the ground eyelet with the air cleaner housing mounting bolt.

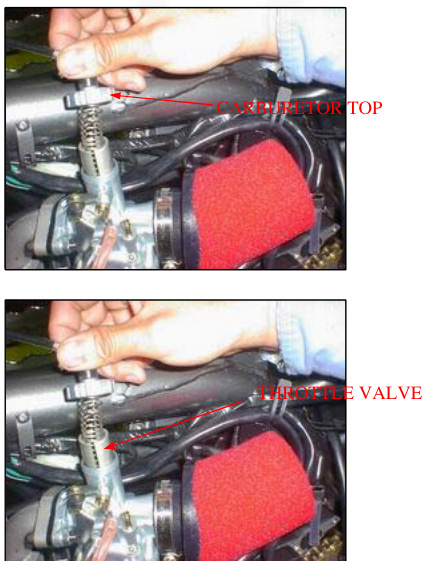

Carburetor Removal

Throttle Valve

Loosen the carburetor top.

Remove the carburetor top and throttle valve from the carburetor.

Remove the throttle cable from the throttle valve while compressing the throttle valve spring.

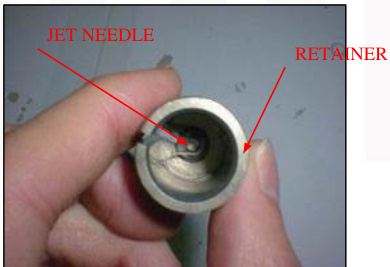

Remove the jet needle retainer and jet needle.

Check the throttle valve and jet needle for scratches, wear, or damage.

Carburetor Body

WARNING: Gasoline is extremely flammable and explosive under certain conditions. Work in a well-ventilated area. Smoking or allowing flames or sparks in the work area or where the gasoline is stored can cause a fire or explosion.

Loosen the drain screw and drain the fuel from the float chamber into an approved gasoline container.

Disconnect the fuel tube, air vent tube, and drain tube from the carburetor body.

Loosen the carburetor connecting tube band screw. Remove# Carburetor Disassembly

Remove the carburetor mounting bolts, carburetor, and insulator.

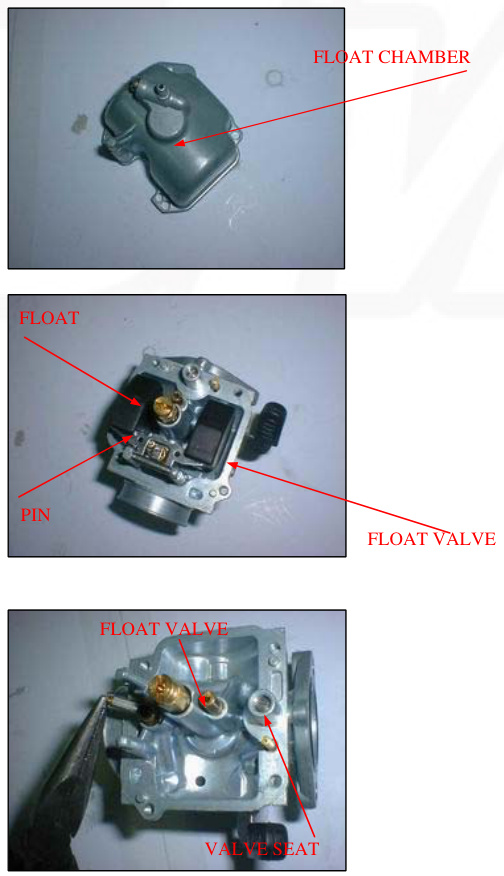

Remove the screws and float chamber.

Remove the float pin, float, and float valve. Inspect the float for deformation or damage.

Inspect the float valve seat for scores, scratches, clogging, and damage. Check the tip of the float valve where it contacts the valve seat for stepped wear or contamination. Replace the valve if the tip is worn or contaminated. Check the operation of the float valve.

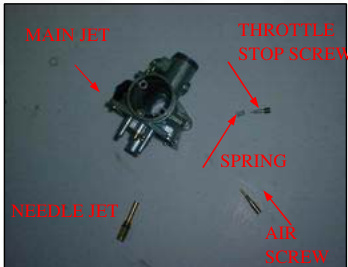

Remove the following:

- Main jet

- Needle jet

- Throttle stop screw and spring

Turn the air screw in and carefully count the number of turns until it seats lightly. Make a note of this for use as a reference when reinstalling the air screw.

Remove the air screw and spring.

CAUTION:

Damage to the air screw seat will occur if the air screw is tightened against the seat.

Inspect each jet for wear or damage and replace if necessary. Clean the jets with cleaning solvent and blow with compressed air.

Fuel System

Blow open each air and fuel passage in the carburetor body with compressed air.

Install the following:

- Throttle stop screw and spring

- Needle jet

- Main jet

CAUTION

Handle all jets with care. They can easily be scored or scratched.

Install the air screw with the spring and return it to its original position as noted during removal. Perform the air screw adjustment procedure if a new air screw is installed (page 5-10).

Hang the float valve onto the float arm lip. Install the float and float valve in the carburetor body, then install the float pin through the body and float.

Float Level Inspection

NOTE:

Set the float level gauge so that it is perpendicular to the float chamber face and in line with the main jet.

With the float valve seated and the float arm just touching the valve, measure the float level with the special tool as shown.

- FLOAT LEVEL: 19mm (0.75in)

- TOOL: Carburetor float level gauge 07401-001000

The float cannot be adjusted. Replace the float assembly if the float level is out of specification. Install a new o-ring into the carburetor groove properly. Install the float chamber.

Install and tighten the float chamber screws.

Fuel System

CARBURETOR INSTALLATION CARBURETOR BODY

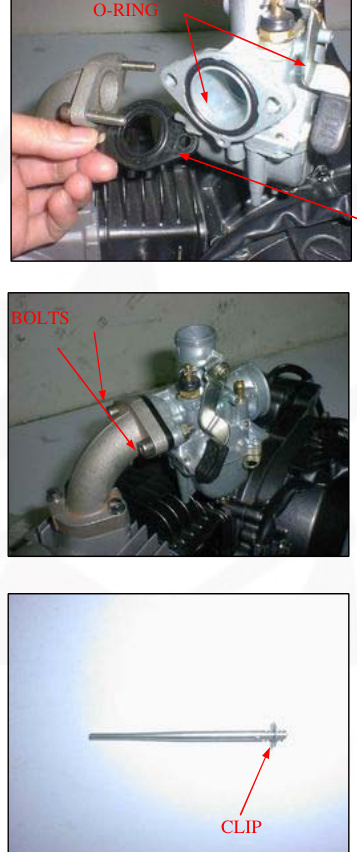

Install new o-ring into the insulator and carburetor body grooves.

INSULATOR

Install the carburetor body into the air cleaner connection tube and the insulator between the manifold and carburetor, then install the mounting bolts. Tighten the connecting tube band screw and mounting bolts.

TORQUE:

- Connecting tube: 1N.m (0.1kgf.m, 0.7lbf.t)

Fuel System

Install the jet needle into the throttle valve and secure it with the needle clip retainer.

Check the seal ring is in good condition, replace if necessary. Install the throttle valve spring onto the throttle cable.

Connect throttle cable to the throttle valve while compressing the throttle valve spring.

Install the throttle valve into the carburetor body, aligning its cut-out with the throttle stop screw.

6. ENGINE REMOVAL AND INSTALLATION

SERVICE INFORMATION

GENERAL

During engine removal and installation, support the motorcycle securely using a hoist or equivalent. Support the engine using a jack or other adjustable support for ease of engine hanger bolts removal. The following components can be serviced with the engine installed in the frame:

- alternator/cam chain tensioner (section 10)

- clutch (section 9)

- cylinder/piston (section 8)

- cylinder head/valves (section 7)

- gearshift linkage (section 9)

- oil pump (section 4)

The crankshaft, transmission, and kickstarter require engine removal for service (section 11).

SPECIFICATIONS

| ITEM | SPECIFICATIONS |

|---|---|

| Engine dry weight | 21kg (46.3lbs) |

TORQUE VALUES

- Drive sprocket fixing plate bolt: 12N.m (1.2kgf.m, 9lbf.ft)

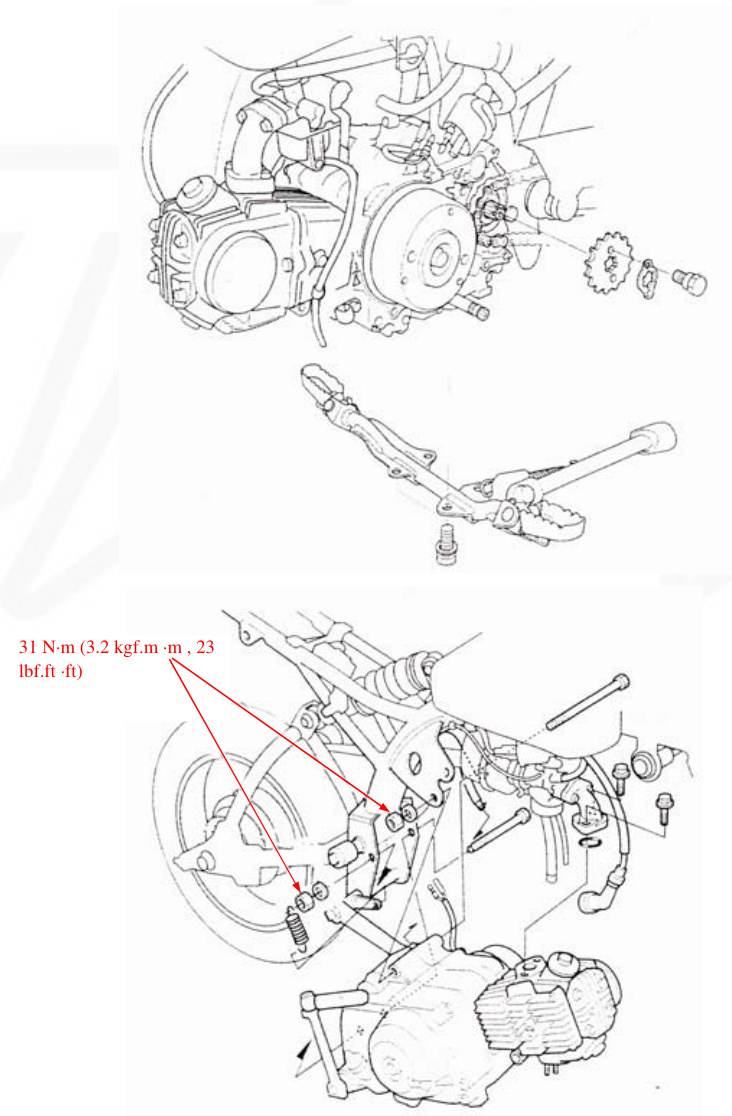

- Engine hanger nut (upper): 31N.m (3.2kgf.m, 23lbf.ft)

- Engine hanger nut (lower): 31N.m (3.2kgf.m, 23lbf.ft)

ENGINE REMOVAL

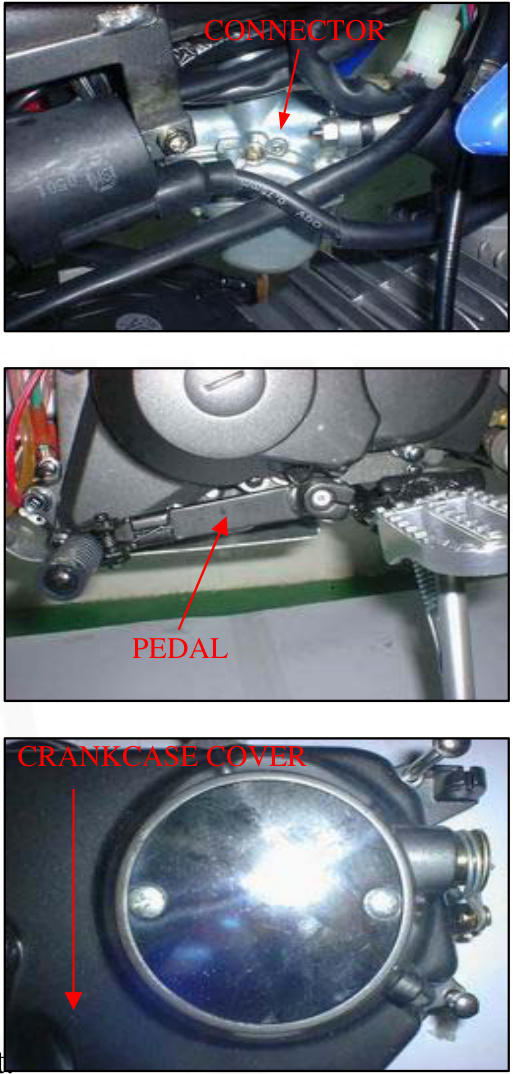

Drain the engine oil (page 3-9). Remove the following:

- exhaust system (page 2-5)

- left crankcase cover (page 10-2)

Disconnect the following:

- spark plug cap

- crankcase breather tube

Remove the following from the clamp:

- carburetor drain tube

Loosen the rear axle nut and drive chain adjusters to loosen the drive chain (page 3-12)

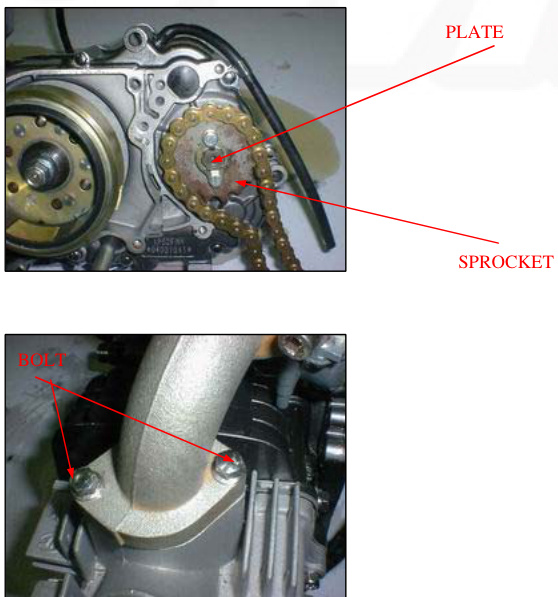

Remove the following:

- fixing plate bolts

- fixing plate

- drive sprocket

- intake manifold bolts

- O-ring

- brake pedal return spring

- four bolts and foot peg bar

Support the motorcycle securely.

ENGINE# REMOVAL AND INSTALLATION

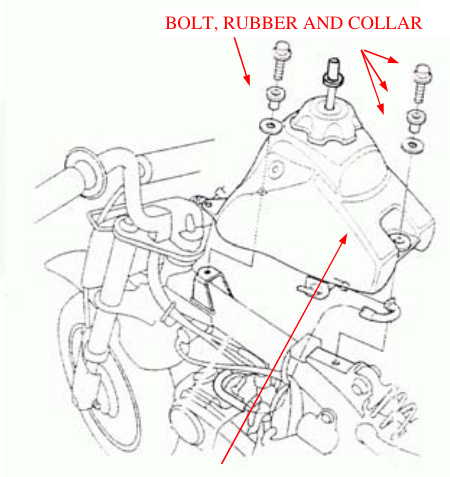

Engine Hanger Nuts and Washers

Place the floor jack or other adjustable support under the engine.

Remove the hanger bolts and the engine from the frame.

CAUTION

During engine assembly removal, hold the engine securely and be careful not to damage the frame and engine.

ENGINE INSTALLATION

Install the engine into the frame in the reverse order of removal.

NOTE

- Note the installation of the hanger bolts. All bolts are installed from the left side.

- The jack height must be continually adjusted to relieve stress from the hanger bolts.

Tighten the hanger nuts to the specified torque.

TORQUE: 31N-m (3.2kgf-m, 23lbf-ft)

Install the removed parts from the engine removal procedure (page 6-2 to 6-3) in the reverse order of removal.

NOTE

- Replace the intake manifold O-ring with a new one.

- Note the installation of the brake pedal return spring.

TORQUE: Fixing plate bolt: 12N-m (1.2kgf-m, 9lbf-ft)

Install the following:

- left crankcase cover (page 10-8)

- exhaust system (page 2-5)

Adjust the drive chain slack (page 3-12)

Fill with the recommended engine oil (page 3-9)

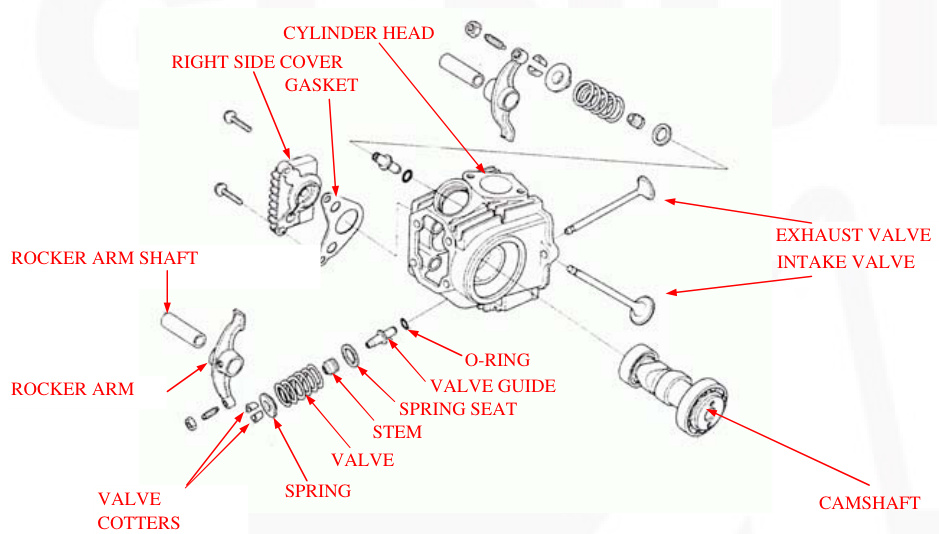

CYLINDER HEAD/VALVES

SERVICE INFORMATION

| CAMSHAFT REMOVAL | |

| TROUBLESHOOTING | |

| CYLINDER HEAD | |

| CYLINDER COMPRESSION | |

| CAMSHAFT INSTALLATION |

SERVICE INFORMATION

GENERAL

This section covers service of the cylinder head, valves, and camshaft.

The cylinder head, valves, and camshaft services can be done with the engine installed in the frame. When disassembling, mark and store the disassembled parts to ensure that they are reinstalled in their original locations.

Clean all disassembled parts with cleaning solvent and dry them off with compressed air before inspection.

Camshaft lubricating oil is fed through oil passages in the cylinder head. Clean the oil passages before assembling the cylinder head.

Be careful not to damage the mating surfaces when removing the cylinder head cover and cylinder head.

Refer to section 10 for cam chain tensioner service.

SPECIFICATIONS

| ITEM | STANDARD |

|---|---|

| Cylinder compression | 981-1,177 kpa (10.0-12.0 kgf/cm2, 142-17lpsi) at 1,000 rpm |

| Cylinder head warpage IN | 0.05±0.02 (0.002±0.001) |

| Valve, valve guide | |

| Valve clearance Valvestem O.D EX | 0.05±0.02 (0.002±0.001) |

| Valve clearance Valvestem O.D IN | 4.970-4.985 (0.1957-0.1963) |

| Valve guide I.D. EX | 4.955-4.970 (0.1951-0.1957) |

| Valve guide I.D. IN/EX | 5.000-5.012 (0.1969-0.1973) |

| Stem-to-guide clearance IN EX | 0.015-0.042 (0.0006-0.0017) 0.030-0.057 (0.0012-0.0022) |

| Valve seat width | 1.0-1.3 (0.04-0.05) |

| Valve spring free length IN/EX(1) | 32.78 |

| Rocker arm/shaft Rocker arm I.D. IN/EX(D) | 35.55 10.000-10. |

| --- | --- |

| Rocker arm shaft O.D. IN/EX | 9.978-9.987 (0.3928-0.3932) |

| Camshaft Cam lobe height 90/110cc | IN 26.563-26.683 (1.046-1.051) |

| Camshaft Cam lobe height 90/110cc | EX 26.326-26.446 (1.036-1.041) |

| Camshaft Cam lobe height 125cc | IN 26.507-26.637 (1.044-1.048) |

11N.m (1.1 kgf.m, 8 lbf.ft) 10N.m (1.0 kgf.m, 7 lbf.ft) 9N.m (0.9 kgf.m, 6.5 lbf.ft)

CYLINDER HEAD/VALVES

TOOLS

| Tool | Part Number |

|---|---|

| Valve spring compressor | 07757-001000 |

| Valve spring compressor attachment | 07959-KM30101 |

| Valve guide reamer,5.0mm | 07742-MA60000 |

| Valve guide reamer,5.0mm | 07984-MA60001 or 07984-MA6000C (U.S.A. Only) |

| Seat cutter,24mm(45.IN) | 07780-0010600 |

| Seat cutter,20.5mm(45.EX) | 07780-0011000 |

| Flat cutter,24mm(32.IN) | 07780-0012500 |

| Flat cutter,21.5mm(32.EX) | 07780-0012800 |

| Interior cutter.22mm(60IN/EX) | 07780-0014202 or 07781-0010400 |

TROUBLESHOOTING

Engine top-end problems usually affect engine performance. These problems can be diagnosed by a compression gauge or by tracing engine noises to the top-end with a sounding rod stethoscope. If the performance is poor at low speeds, check for white smoke in the crankcase breather tube. If the tube is smoky check for a seized piston ring (Section 8).

Compression too low, hard starting or poor performance at low speed

Valves

- Incorrect valve clearance

- Burned or bent valve

- Incorrect valve timing

- Broken valve spring

- Uneven valve seating

Cylinder head

- Leaking or damaged head gasket

- Warped or cracked cylinder head

- Worn cylinder, piston or piston rings (section 8)

Compression too high, overheating or knocking

Excessive carbon build-up on piston crown or on combustion chamber

Excessive noise

Cylinder head

- Incorrect valve clearance

- Sticking valve or broken valve spring

- Damaged or worn camshaft

- Loose or worn cam chain

- Worn or damaged cam chain tensioner

- Worn cam sprocket teeth

- Worn rocker arm and/or shaft

- Worn cylinder, piston or piston rings (section 8)

Rough idle

Low cylinder compression

Excessive smoke

Cylinder head

- Worn valve stem or valve guide

- Damaged stem seal

- Worn cylinder, piston or piston rings (section 8)

CYLINDER COMPRESSION

Warm up the engine to normal operating temperature. Stop the engine and remove the spark plug (page 3-6) Install a compression gauge. Shift the transmission into neutral and open the choke lever (OFF). Open the throttle all the way and crank the engine with the kickstarter until the gauge reading stops rising. COMPRESSION PRESSURE: 981-1,177 kPa (10.0-12.0 kgf/cm2, 142-171 psi) at 1,000 rpm. Low compression can be caused by:

- Blown cylinder head gasket

- Improper valve adjustment

- Valve leakage

- Worn piston ring or cylinder

- High compression# ssion

Common Causes of Issues:

- Carbon deposits in combustion chamber or on piston head

LEFT SIDE COVER

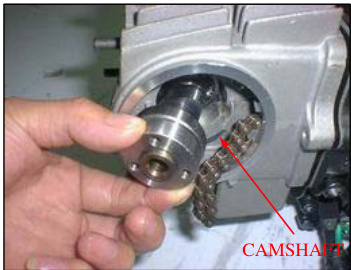

CAMSHAFT REMOVAL

Drain the engine oil (page 3-9)

Remove the following:

- Valve adjuster hole cap (page 3-7)

- Left crankcase cover (page 10-2)

- Sealing bolt, tensioner spring, and tensioner push rod to loosen the cam chain tensioner (page 10-4)

Disconnect the spark plug cap. Loosen the cylinder head side cover 6 mm bolt. Tap the head of the 6mm bolt and release the cylinder head left side cover from the cylinder head. Remove the 6mm bolt, sealing washer, and cylinder head left side cover.

Turn the crankshaft counterclockwise and align the "0" mark on the cam sprocket with the index notch on the cylinder head.

Remove the bolts, cam sprocket, and dowel pin. Secure the cam chain with a piece of wire to prevent it from falling into the cylinder.

7. CYLINDER HEAD/VALVES

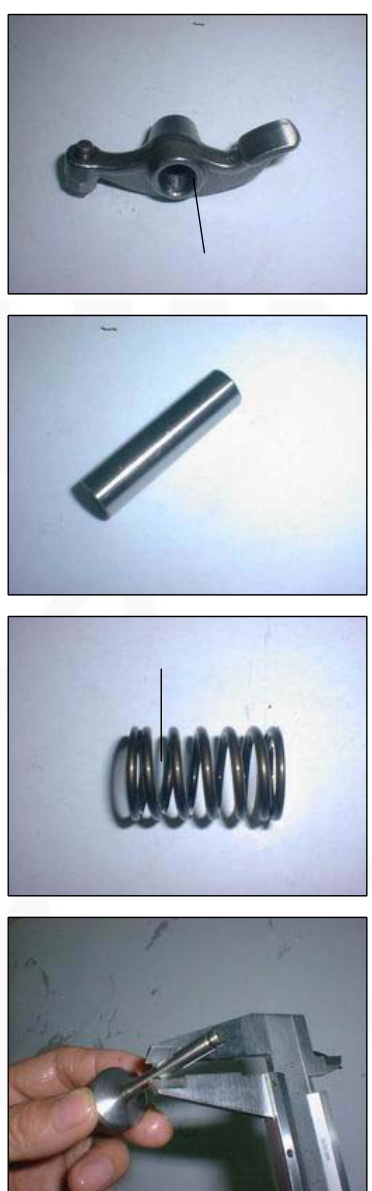

Loosen the valve adjusting screw fully to make a valve clearance maximum (page 3-8). Temporarily install the cam sprocket bolts into the camshaft and remove the camshaft from the cylinder head while holding the rocker arms.

INSPECTION

Turn the outer race of each camshaft bearing with your finger. The outer race should turn smoothly and quietly. Also check that the bearing inner race fits tightly on the camshaft. Replace the camshaft assembly if the outer race does not turn smoothly and quietly or if it fits loosely on the camshaft.

Using a micrometer, measure each cam lobe height.

SERVICE LIMITS: 90/110/125cc :IN:26.22mm (1.032in) EX:25.98mm (1.023in)

Remove the intake manifold bolts.

Remove the following:

- Cap nuts/seating washers

- Nut/sealing washer

- Cylinder head cover

- Gasket

Remove the cylinder head mounting bolt and cylinder head.

Remove the following:

- Gasket

- Dowel pins

- Collar

- O-ring

DISASSEMBLY

Remove the spark plug. Remove the bolts and cylinder head right side cover.

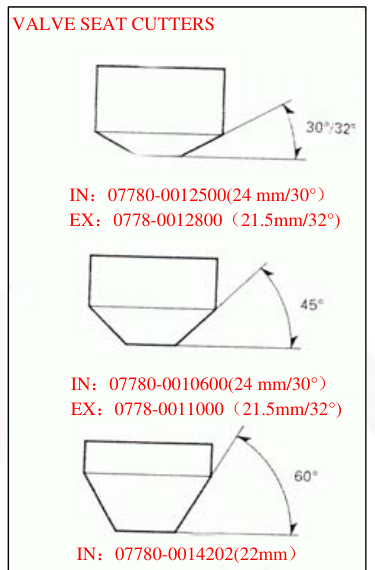

Temporarily install an 8mm bolt to the rocker arm shaft and remove the rocker arm shafts and rocker arms.

7. CYLINDER HEAD/VALVES

Remove the valve springs using the special tools as shown.

TOOLS: Valve spring compressor 07757--0010000. Valve spring compressor attachment 07959--KM30101

CAUTION: To prevent loss of tension, do not compress the valve springs more than necessary to remove the cotters.

Remove the following:

- Spring retainer

- Valve spring

- Valve

- Stem seal

- Valve spring seat

- Cotters

INSPECTION

CYLINDER HEAD Remove carbon deposits from the combustion chamber.

Spark Plug Hole and Valve Areas

Check for cracks in the spark plug hole and valve areas. Avoid damaging the gasket surface. Check the cylinder head for warpage with a straight edge and feeler gauge.

SERVICE LIMIT: 0.05mm (0.002 in)

Cylinder Head/Valves

Rocker Arm

Inspect the rocker arm slipper surfaces for wear or damage. Also, check that the oil holes are not clogged. Measure the rocker arm I.D. If either rocker arm requires service or replacement, inspectInspect the cam lobes for scoring, chipping, or flat spots.

SERVICE LIMIT: IN/EX > 10.10mm (0.398 in)

Inspect the rocker arm shafts for wear or damage. Measure the O.D. of the rocker arm shaft.

SERVICE LIMIT: IN/EX: 9.91mm (0.390 in)

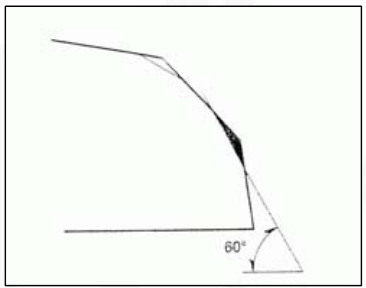

Valve Spring

Measure the free length of the inner and outer valve springs.

SERVICE LIMITS: IN/EX: 31.8mm (1.25 in)

Replace the springs if they are shorter than the service limits.

Valve

Inspect each valve for bending, burring, or abnormal stem wear. Check valve movement in the guide. Measure and record each valve stem O.D.

SERVICE LIMIT: IN/EX: 4.92mm (0.194 in)

Ream the guides to remove any carbon deposits before measuring the guide. Insert the reamer from the combustion chamber side of the head and always rotate the reamer clockwise.

TOOL: Valve guide reamer, 5.0 mm 07984--MA60001 or 07984--MA6000C (U.S.A only)

Measure and record each valve guide I.D.

SERVICE LIMIT: IN/EX: 5.03mm (0.198 in)

Subtract each valve stem O.D. from the corresponding guide I.D. to obtain the stem-to-guide clearance.

SERVICE LIMITS: IN: 0.08mm (0.003in), EX: 0.10mm (0.004in)

If the stem-to-guide clearance is out of specification, determine if a new guide with standard dimensions would bring the clearance within tolerance. If so, replace any guides as necessary and ream to fit. If the stem-to-guide clearance is out of specification with a new guide, also replace the valve. Reface the valve seats whenever the valve guides are replaced (page 7-9).

Valve Guide Replacement

Chill new valve guides in the freezer section of a refrigerator for about an hour. Heat the cylinder head to 212-302°F (100-150°C) with a hot plate or oven.

Warning

To avoid burns, wear heavy gloves when handling the heated cylinder head.

Caution

Do not use a torch to heat the cylinder head; it may cause warping. Support the cylinder head and drive out the valve guides from the combustion chamber side.

TOOL: Valve guide driver, 5.0mm, 07492-MA60000

Coat new O-rings with engine oil and install them onto new valve guides. While the cylinder is still heated, drive the guides in the cylinder head from the camshaft side until they are fully seated.

TOOL: Valve guide driver, 5.0mm 07942-MA60000

Let the cylinder head cool to room temperature.

Ream the new valve guide after installation. Insert the reamer from the combustion chamber side of the head and always rotate the reamer clockwise.

TOOL: Valve guide reamer, 5.0mm 07984-MA600001 or 07984-MA60000C

NOTE: Use cutting oil on the reamer during this operation.

Clean the cylinder head thoroughly to remove any metal particles. Reface the valve seat (see below)

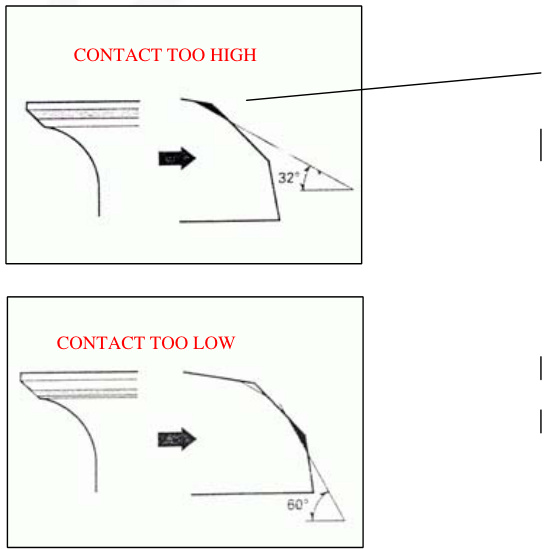

VALVE SEAT INSPECTION/REFACING

Clean the intake and exhaust valves thoroughly to remove carbon deposits. Apply a light coating of Prussian Blue to the valve seats. Lap the valves and seats using a rubber hose or other hand-lapping tool. Remove and inspect the valves. CAUTION: The valves cannot be ground. If a valve face is burned or badly worn, or if it contacts the seat unevenly, replace the valve.

Inspect the width of each valve seat. STANDARD: 1.0 - 1.3 mm (0.04 - 0.05 in) SERVICE LIMIT: 2.0 mm (0.08 in)

If the seat is too wide, too narrow, or has low spots, the seat must be ground.

VALVE SEAT REFACING

Valve seat cutters/grinders equivalent valve seat refacing equipment are recommended to correct worn valve seats.

NOTE: Follow the refacing manufacturer's operation instructions.

Use a 45-degree cutter to remove any roughness or irregularities from the seat. Reface the seat with a 45-degree cutter whenever a valve guide is replaced.

Use a 32-degree (IN:30) cutter to remove the top 1/4 of the existing valve seat material.

CYLINDER HEAD/VALVES

Use a 60-degree cutter to remove the bottom 1/4 of the old seat. Remove the cutter and inspect the area you have refaced. Install a 45-degree finish cutter and cut the seat to the proper width. Make sure that all pitting and irregularities are removed. Refinish if necessary.

Apply a thin coating of Prussian Blue to the valve seat. Press the valve through the valve guide and onto the seat to make a clear pattern. NOTE: The location of the valve seat in relation to the valve face is very important for good sealing. If the contact area is too high on the valve, the seat must be lowered using a 32-degree flat cutter. If the contact area is too low on the valve, the seat must be raised using a 60-degree cutter.

Refinish the seat to specifications using a 45-degree finish cutter.

CYLINDER HEAD/VALVES

After cutting the seat, apply lapping compound to the valve face, and lap the valve using light pressure. Do not allow lapping compound to enter the guides.

After lapping, wash all residual compound off the cylinder head and valve.

ASSEMBLY

Clean the cylinder head assembly with solvent and blow through all oil passages with compressed air.

Install the valve stems with engine oil and insert the valve into`the valve guide. To avoid damage to the stem seal, turn the valve slowly when inserting. Install the valve springs with the tightly wound coils facing the combustion chamber. Install the valve spring retainer.

CYLINDER HEAD/VALVES

Install the valve cotters using the special tool as shown.

TOOL: Valve spring compressor 07757-0010000 Valve spring compressor attachment 07959-KM30101

CAUTION

Support the cylinder head above the workbench so that the valve heads will not contact anything that can cause damage.

Apply engine oil to the rocker arm inner and slipper surfaces. Install the rocker arms and rocker arm shafts. Install the rocker arm shaft with its threaded end facing the right side.

Install a new gasket onto the cylinder head right side cover. Install the right side cover onto the cylinder head.

Install the right side cover bolts.

INSTALLATION

Clean off the gasket material from the cylinder surface.

Install the following:

- New O-ring

- Collar

- Dowel

- New gasket

Route the cam chain through the cylinder head and install the cylinder head.

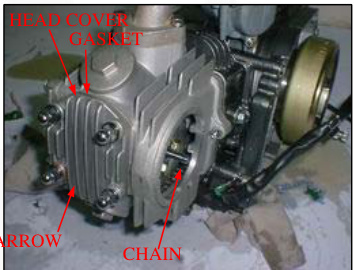

Install a new gasket onto the cylinder head and then install the cylinder head cover.

Install the cylinder head cover with its arrow mark facing down.

CYLINDER HEAD/VALVES

Install the following:

- Cap nuts/new sealing washers

- Nut/new sealing washer

NOTE: Note the position of the washers and nuts.

Tighten the cylinder head cover nuts to the specified torque.

TORQUE: 11N.m(1.1 kgf.m, 8lbf.ft)

Install and tighten the cylinder head mounting bolt. If the cylinder was removed, tighten the cylinder mounting bolt. Install a new O-ring into the groove. Move in the intake manifold.

NUT

Install and tighten the intake manifold bolts. Install the following:

- Spark plug (page 3-7)

- Muffler (page 2-4)

CAMSHAFT INSTALLATION

Apply clean engine oil to the camshaft lobes and bearings. Install the camshaft into the cylinder head with its cam lobes facing the combustion chamber while holding the rocker arms.

CYLINDER HEAD/VALVES

Turn the crankshaft counterclockwise and align theAlign the "T" mark with the index notch on the left crankcase.

CYLINDER HEAD/VALVES

Install the tensioner push rod, spring, and sealing bolt (page 10-5).

Adjust the valve clearance (page 3-7). Pour the recommended engine (page 3-9).

CYLINDER/PISTON

| SERVICE INFORMATION | CYLINDER/PISTON INSPRCTION |

|---|---|

| TROUBLESHOOTING | PISTON INSTALLATION |

| CYLINDER REMOVAL | CYLINDER INSTALLATION |

| PISTON REMOVAL |

SERVICE INFORMATION

GENERAL

The cylinder and piston service can be done with the engine installed in the frame. Camshaft lubrication oil is fed to the cylinder head through an orifice in the cylinder head, cylinder, and crankcase. Make sure that the orifice is not clogged and that the O-ring and dowel pins are in place before installing the cylinder.

SPECIFICATIONS

| ITEM | STANDARD |

|---|---|

| Cylinder | 39.005-39.015(1.5356-1.5360) |

| Out of round | |

| Taper | |

| Warpage Piston mark direction | |

| Piston rings | "IN" mark facing toward the intake side |

| Piston O.D. measurement point Piston pin bore I.D. 8mm(0.3in) from bottom of skirt 13.002-13.008(0.5119-0.5121) | |

| Piston pin O.D. | |

| Piston-to-piston pin clearance 12.994-13.000(0.5116-0.5118) 0.002-0.014(0.0001-0.0006) | |

| Piston ring-to-ring Top/Second 0.015-0.050(0.0006-0.0020) | |

| Parameter | Measurement Range |

| ----------- | ------------------- |

| Groove Clearance | Piston ring end gap |

| Top Second | 0.05-0.15(0.002-0.0016) |

| Oilsiderail | 0.05-0.20(0.002-0.0016) |

| Cylinder-to-piston clearance | 0.3-0.9(0.01-0.04) 0.010-0.040(0.0004-0.0016) |

| Connectingrod small end I.D Connectingrod-to-pistonpinclearance | 13.016-13.034(0.5124-0.5131) |

| 0.016-0.040(0.0006-0.0016) |

TORQUE VALUES

Cam chain guide roller in bolt

TROUBLESHOOTING

If the performance is poor at low speeds, check for white smoke in the crankcase breather tube. If the tube is smoky, check for a seized piston ring. Cylinder compression is too low, or engine is hard to start. Blown cylinder head gasket. Worn, stuck, or broken piston ring. Worn or damaged cylinder or piston.

Piston sounds: Worn cylinder, piston, and/or piston ring. Worn piston pin hole and piston pin. Worn connecting rod small end.

Cylinder compression is too high, or engine overheats or knocks due to carbon deposits on the cylinder head and/or piston crown.

Excessive smoke from worn, stuck, or broken ring.# R REMOVAL

Remove the cylinder head (page 7-4)

Remove the cam chain guide roller bolt, washer, and guide roller. Remove the mounting bolt and cylinder. Remove the following:

- Rubber packing

- Gasket

- Dowel pins

PISTON REMOVAL

Remove the piston clip with pliers. Press the piston pin out of the piston and remove the piston.

Note: Do not let the piston pin clips fall into the crankcase.

Remove the piston rings. Do not damage the piston rings during removal.

SERVICE LIMIT: 39.05mm(1.537in)

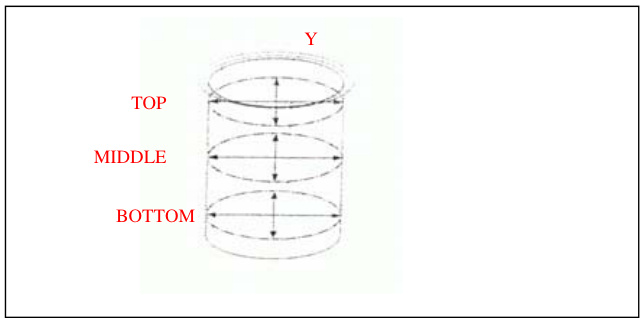

CYLINDER/PISTON INSPECTION

Inspect the cylinder bore for wear or damage. Measure the cylinder I.D. in X and Y axis at three levels. Take the maximum reading to determine the cylinder wear. Calculate the piston-to-cylinder clearance. Take a maximum reading to determine the clearance. Refer to page 8-5 for measurement of piston O.D.

SERVICE LIMIT: 0.15mm(0.006in) Calculate the taper and out of round at three levels in X and Y axis. Take the maximum reading to determine them. SERVICE LIMIT: Taper: 0.10mm(0.004in) Out of round: 0.10mm(0.004in)

The cylinder must be rebored, and an oversized piston fitted if the service limits are exceeded.

The following oversize pistons are available: 0.25mm(0.010in) 0.50mm(0.020in)

The piston-to-cylinder clearance for the oversize piston must be: 0.010-0.040mm(0.0004-0.0016in).

Inspect the top of the cylinder for warpage.

SERVICE LIMIT: 0.05mm(0.002in)

Remove any carbon deposits from the piston ring grooves, using an old piston ring as shown.

CYLINDER/PISTON

Temporarily install the piston to their proper position with the mark facing up.

Measure the piston ring-to-ring groove clearance with the rings pushed into the grooves.

SERVICE LIMITS:

Top: 0.12mm(0.005in)

Second: 0.12mm(0.005in)

Inspect the piston for wear or damage.

Measure the diameter of the piston at 8mm(0.3in) from the bottom and 90 degrees to the piston pin hole.

SERVICE LIMIT: 38.90mm(1.531in)

Measure the piston pin bore. SERVICE LIMIT: 13.06mm(0.514in)

Measure the O.D. of the piston pin. SERVICE LIMIT: 12.98mm(0.511in)

Calculate the piston-to-piston pin clearance. SERVICE LIMIT: 0.08mm(0.003in)

Measure the connecting rod small end I.D. SERVICE LIMIT: 13.08MM(0.515in)

Calculate the connecting rod-to-piston pin clearance. SERVICE LIMIT: 0.12mm(0.005in)

Insert the piston rings squarely into the bottom of the cylinder and measure the ring end gap.

SERVICE LIMITS: Top: 0.5mm(0.02in) Second: 0.5mm(0.02in) Oil side rail: 1.1mm(0.04in)

Push the ring into the cylinder with the top of the piston to be sure they are squarely in the cylinder.

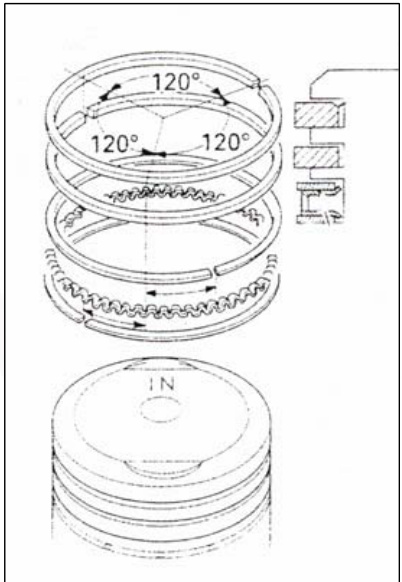

PISTON RING INSTALLATION

Clean the piston ring grooves thoroughly and install the piston rings.

NOTE:

- Apply oil to the piston rings.

- Avoid piston and piston ring damage during installation.

- Install the piston rings with their marking facing up.

- Do not confuse the top and second rings.

- Space the piston ring end gaps 120 degrees apart.

- Do not align the gaps in the oil rings side rails.

After installation, the rings should rotate freely in the ring grooves.

PISTON INSTALLATION

Apply oil to the piston pin outer surface. Install the piston with its "IN" mark facing the intake side. Install the piston pin and secure it with new piston pin clips.

NOTE:

- Do not align the piston pin clips end gap with the piston cut-out.

- Do not let the piston pin clips fall into the crankcase.

CYLINDER INSTALLATION

Clean off any gasket materials from the crankcase surface.

Install the dowel pins, new gasket, and new rubber packing.

Coat the cylinder bore, piston outer surface, and piston ring grooves with clean engine oil. Route the cam chain through the cylinder and install the cylinder while compressing the piston rings.

NOTE: Avoid piston ring damage during installation. Do not let the cam chain fall into the crankcase.

Apply engine oil to the guide roller inner surface. Install the cam chain guide roller, new sealing washer, and pin bolt. Tighten the cam chain guide roller pin bolt to the specified torque.

TORQUE: 10N.m (1.0kgf.m, 7lbf.ft)

Install the cylinder mounting bolt but do not tighten it yet. Install the cylinder head (page 7-14).

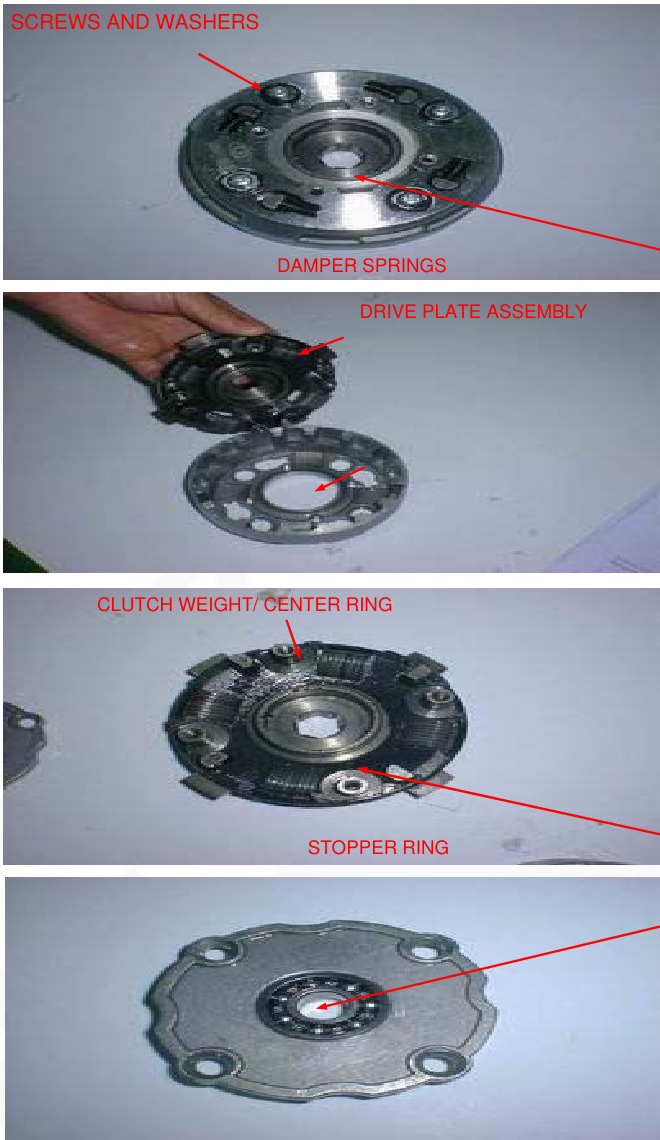

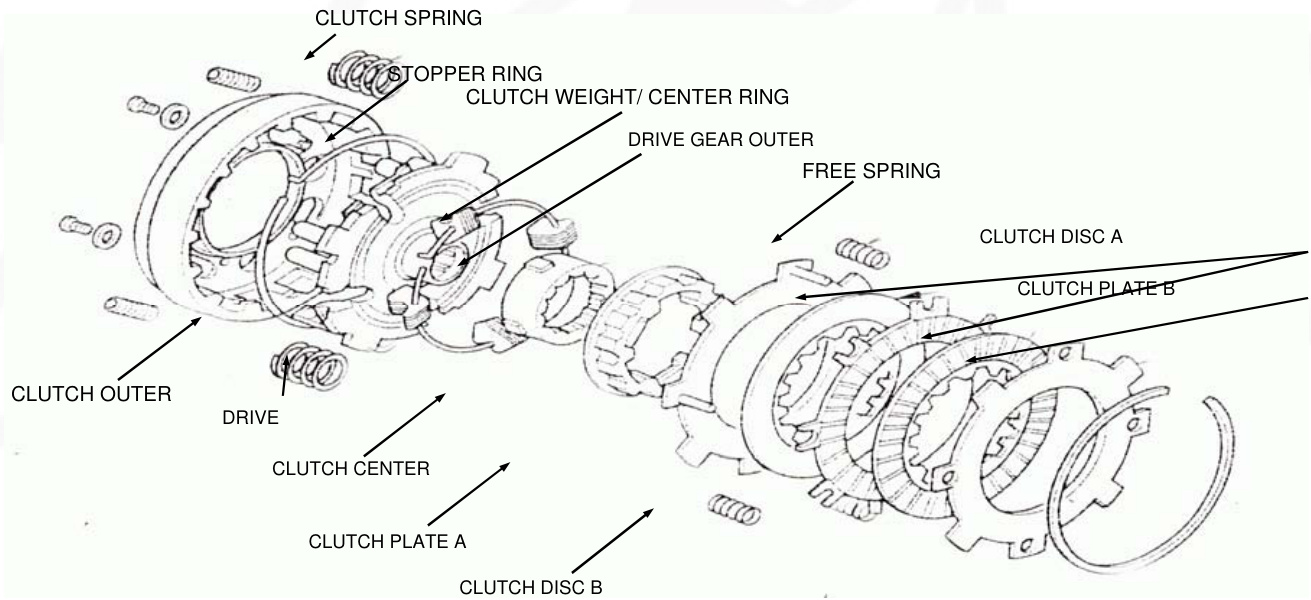

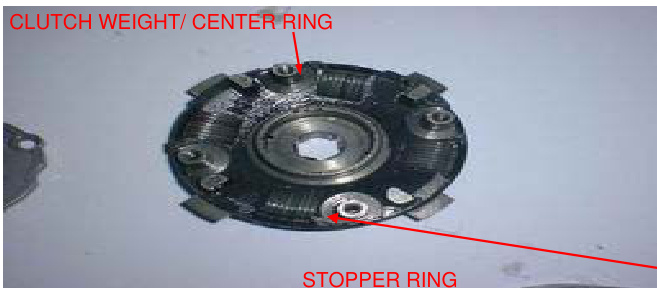

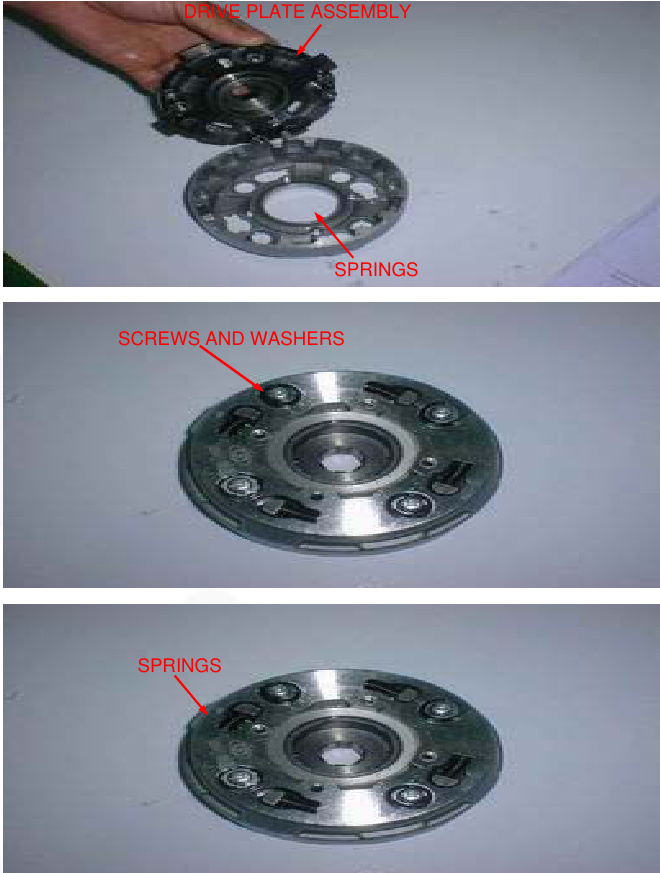

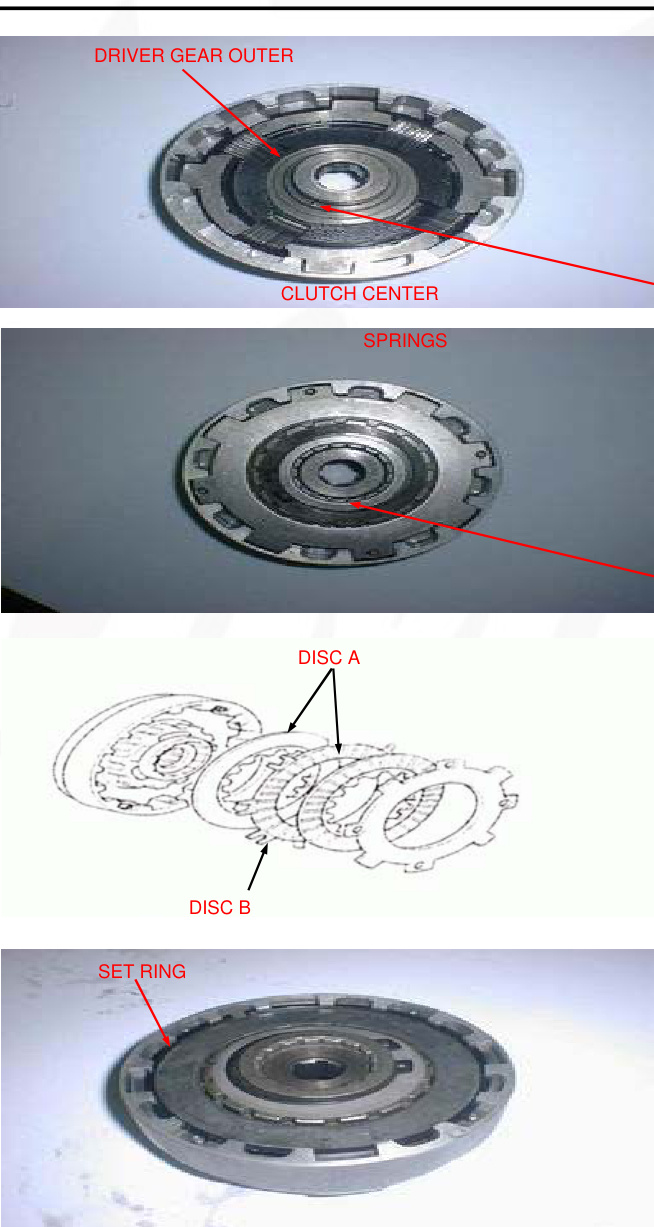

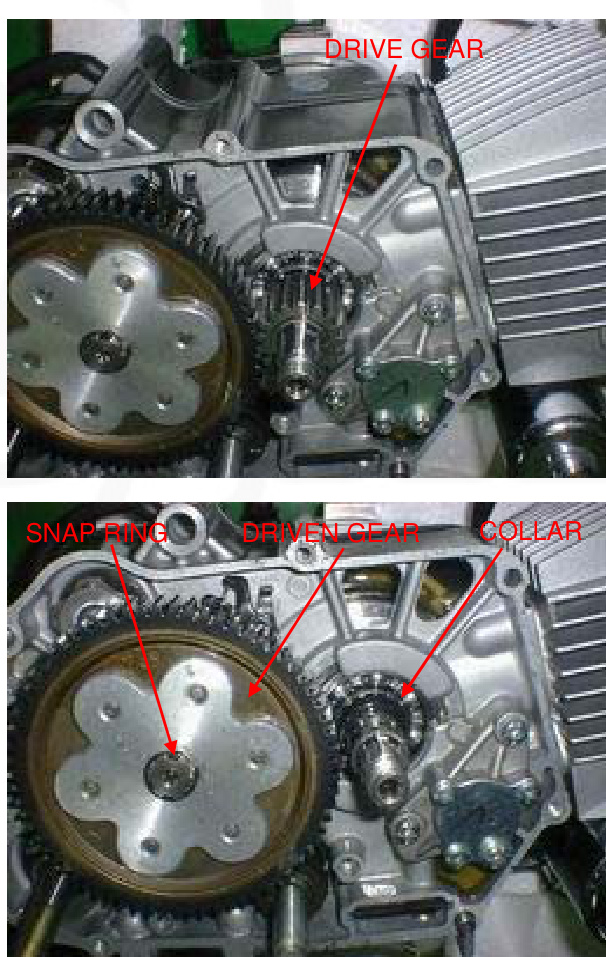

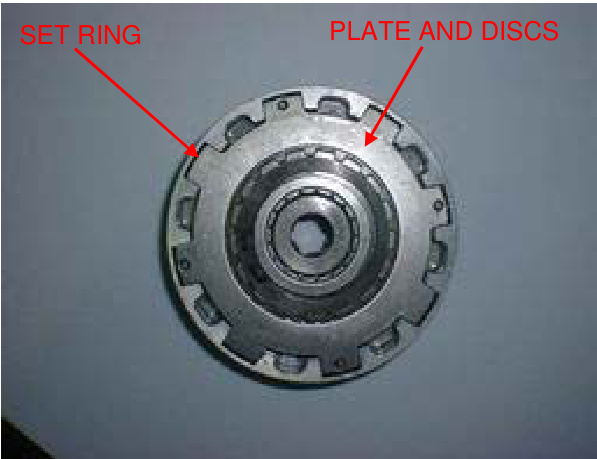

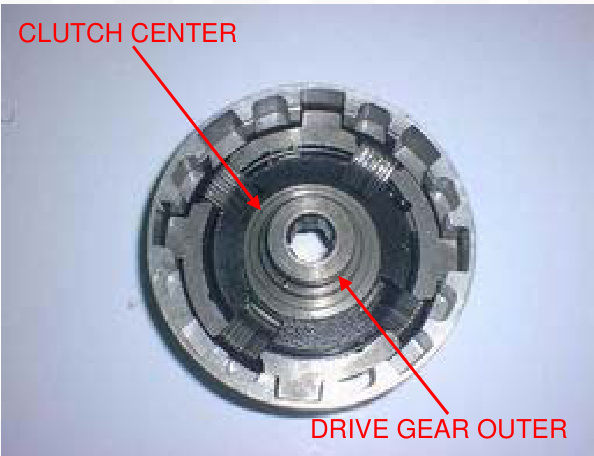

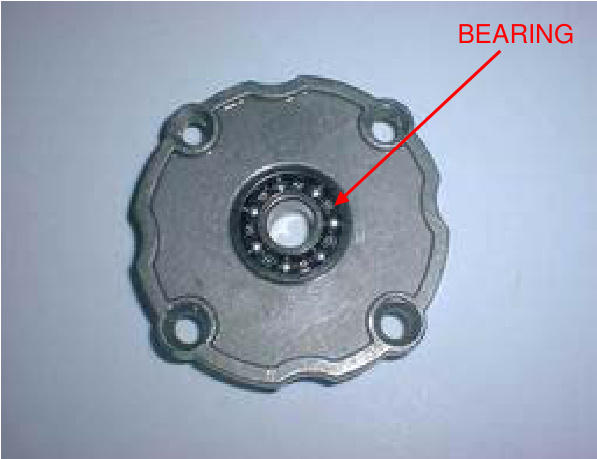

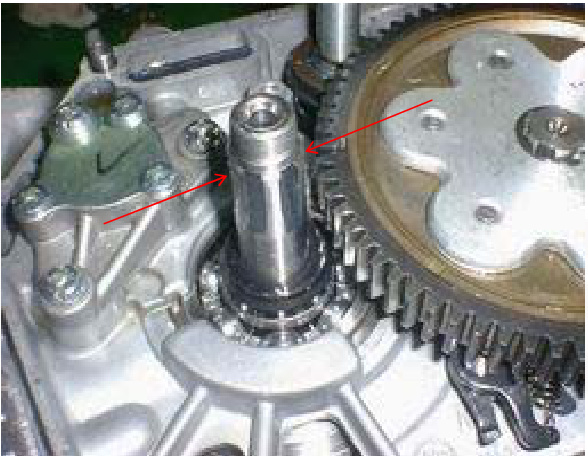

SERVICE INFORMATION

GENERAL

This section covers service of the clutch and gearshift linkage. All service can be done with the engine installed in the frame.

Use care not to allow dust or dirt to enter the engine.

Transmission oil viscosity and level have an effect on clutch disengagement. When the clutch does not disengage or the motorcycle creeps with the clutch disengaged, inspect the transmission oil level before servicing the clutch system.

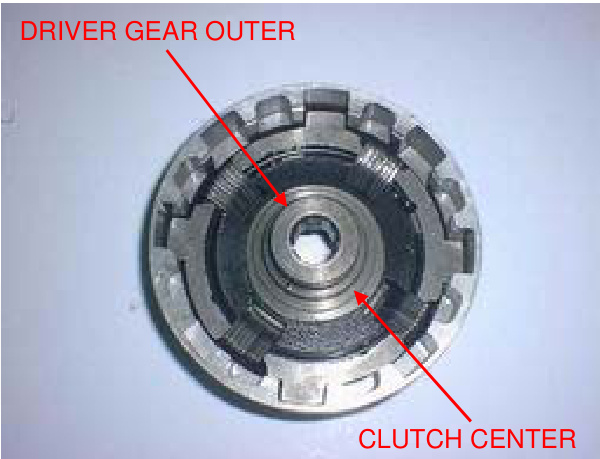

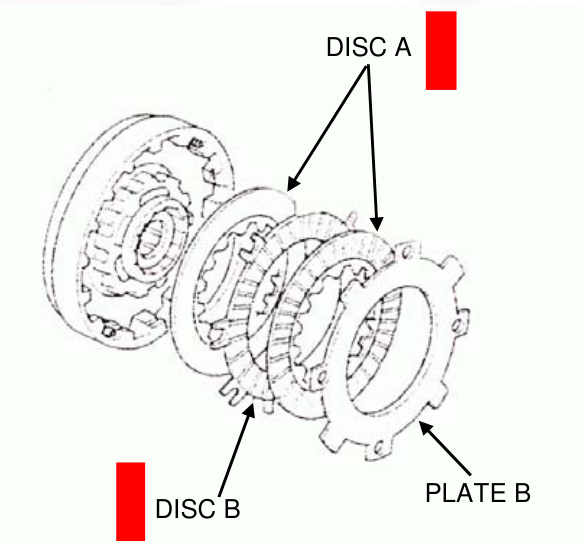

SPECIFICATIONS

| ITEM | STANDARD | SERVICE LIMIT |

|---|---|---|

| Clutch disc thickness A | A: 1.52-1.68 (0.060-0.066) | 1.3 (0.051) |

| B: 3.42-3.58 (0.135-0.141) | 3.2 (0.126) | |

| Clutch plate warpage | 0.20 (0.008) | |

| Centrifugal clutch spring free length | 19.5 (0.77) : 20 (0.79) | |

| Pri | Part | Measurement (in mm and inch) |

| ------------------------------- | --------------------------------------------- | ------------------------------------- |

| Mary drive gear | 21.0000-21.021 (0.8268- 0.8276) | 19.4 (0.76) |

| Clutch center guide | L.D 16.988-17.006 (0.6688-0.6695) O.D 20.930-20.950 (0.8240-0.8248) | 21.05 (0.829) 17.04 (0.671) |

| Crankshaft O.D. at clutch center guide | 16.966-16.984 (0.6680-0.6687) | 20.9 (0.823) 16.9 (0.665) |

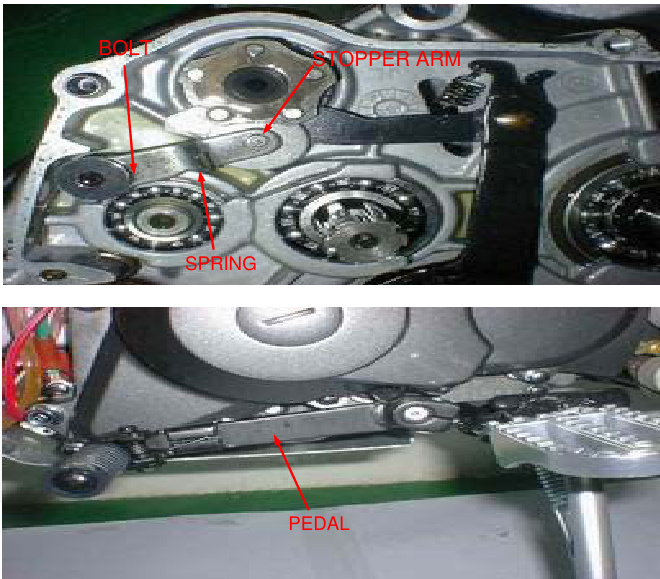

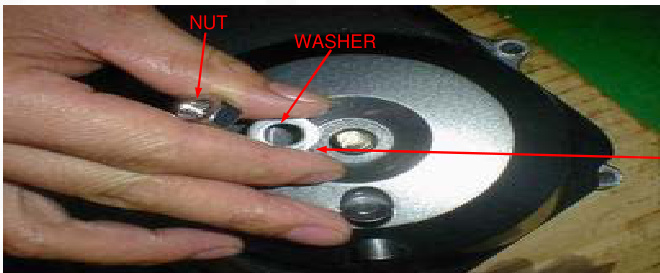

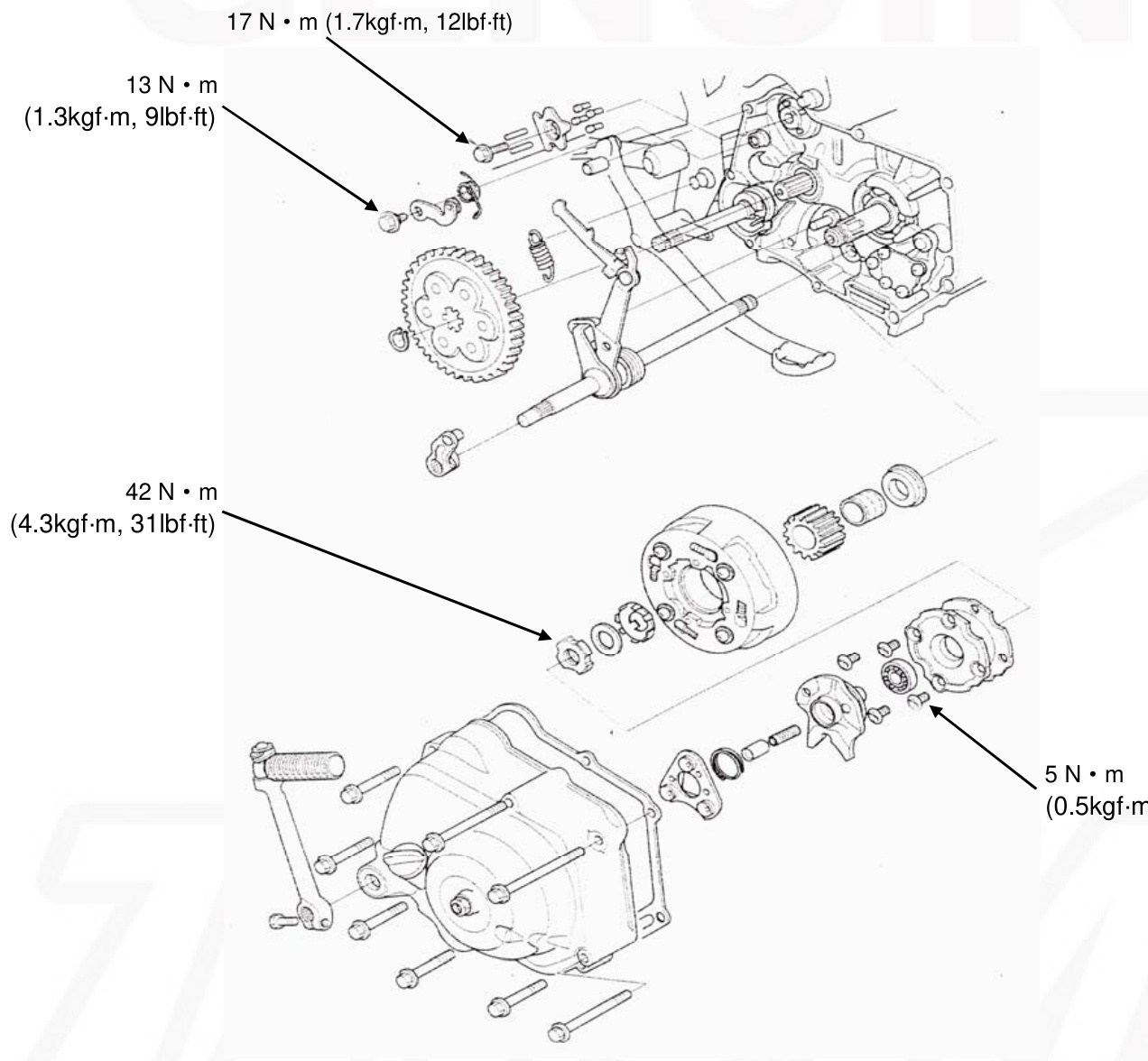

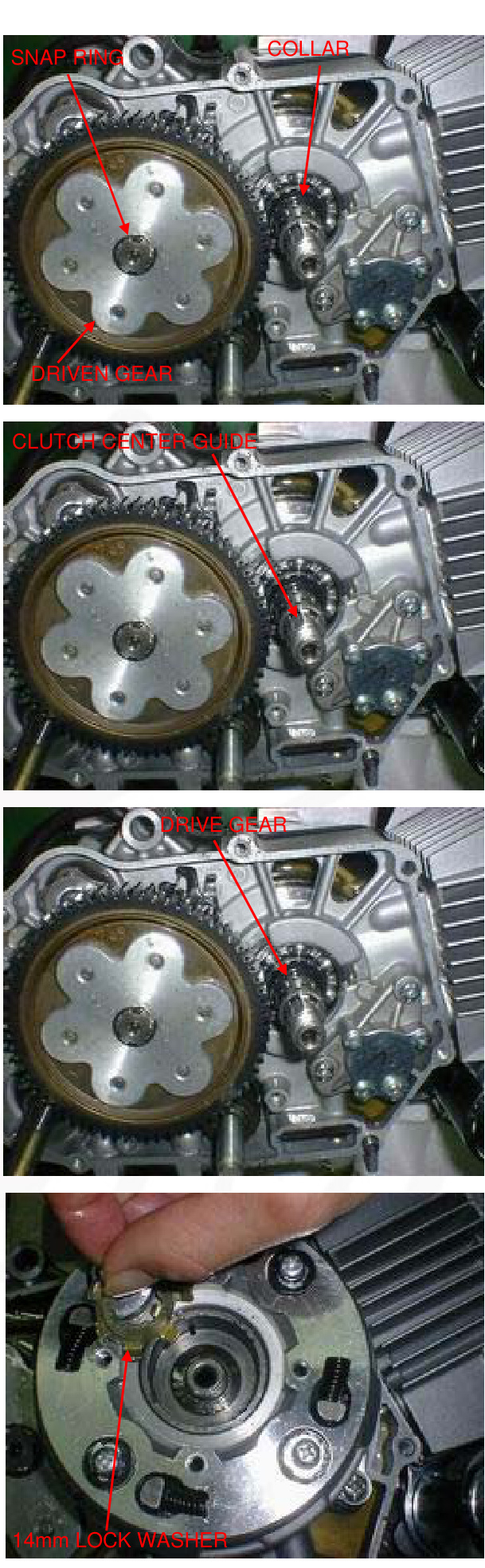

TORQUE VALUES

- Clutch outer cover screw: 5N.m (0.5kgf.m, 3.6lbf.ft)

- Clutch lock nut

- Clutch assembly screw

- Shift drum stopper arm bolt

- Shift return spring pin bolt

- Gearshift cam plate bolt: 42N.m (4.3kgf.m, 31lbf.ft)

| bf.ft | Torque Values |

|---|---|

| 6 N.m (0.5 kgf.m, 3.6 lbf.ft) | |

| 13 N.m (1.3 kgf.m, 9 lbf.ft) | |

| 29 N.m (3.0 kgf.m, 22 lbf.ft) | |

| 17 N.m (1.7 kgf.m, 12 lbf.ft) |

TOOLS

- Flywheel holder

- Lock nut wrench, 20x24mm

- Extension bar

- 07725-0040000

- 07716-0020100

- 07716-0020500

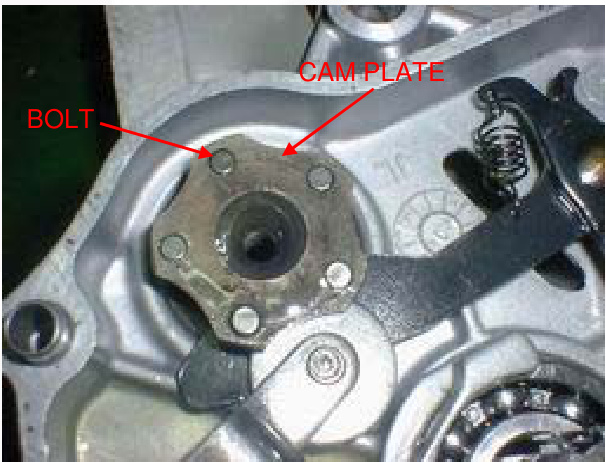

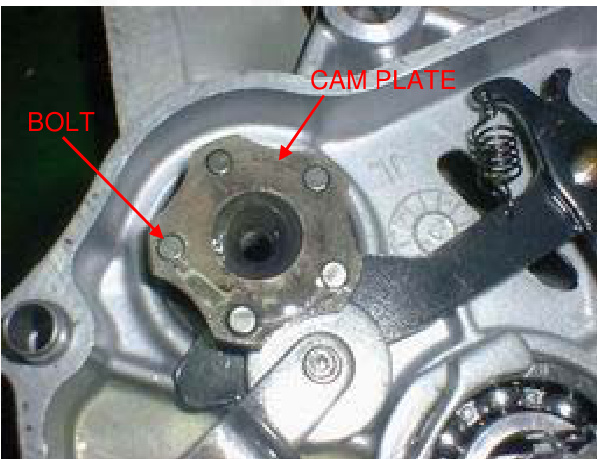

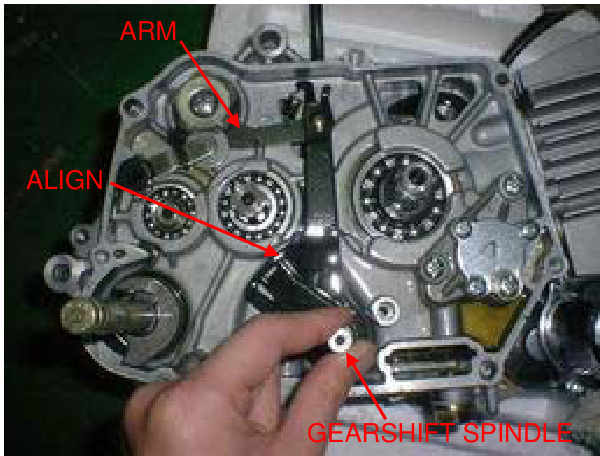

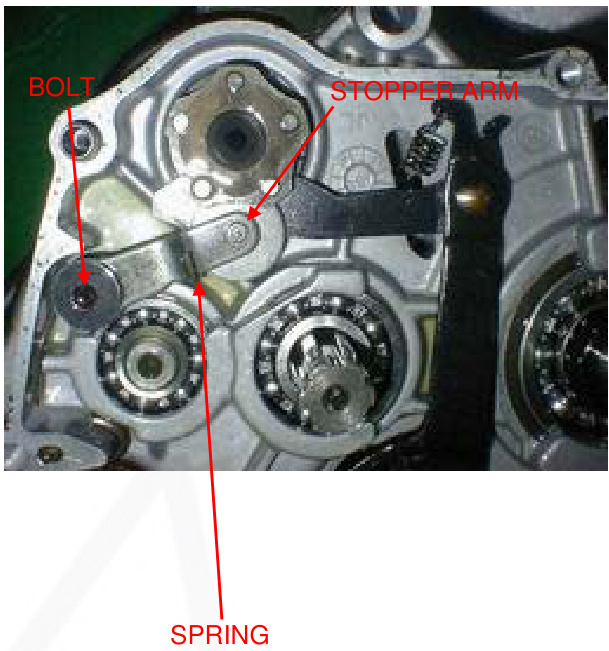

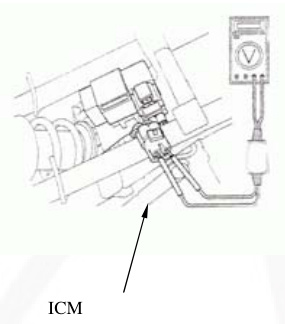

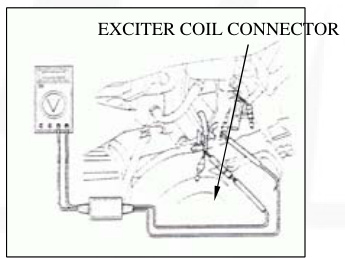

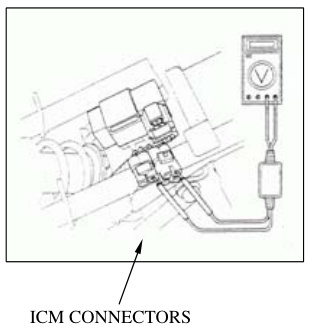

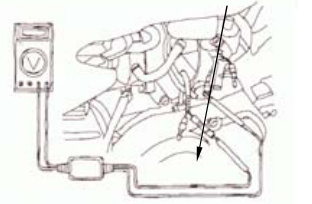

CLUTCH / GEARSHIFT LINKAGE TROUBLESHOOTING